The highly acclaimed AccurioLabel 230 toner Press & new Accurio 400 with White from Konica Minolta is available in the UK, through Focus Label Machinery – an Accredited Industrial Print Partner of Konica Minolta.

This cutting-edge technology is also perfectly complemented by the Focus Reflex range of digital print finishing systems.

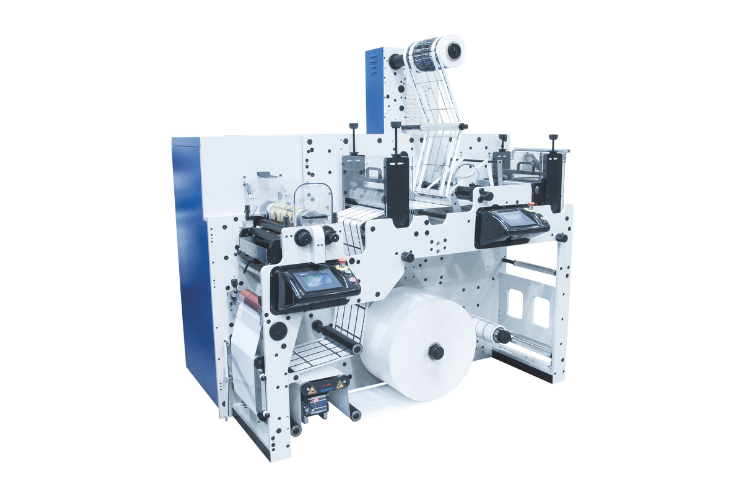

For digitally printed web, the Reflex 330 Digital Finishing System provides a fully comprehensive off-line finishing solution. Focus claims that the Reflex 330 re-register system is extremely accurate – even at speeds well over 100 metres per minute. New for 2023 includes the option for semi-rotary or full rotary converting system for roll-to-roll or roll-to-sheet formats.

AccurioLabel 230

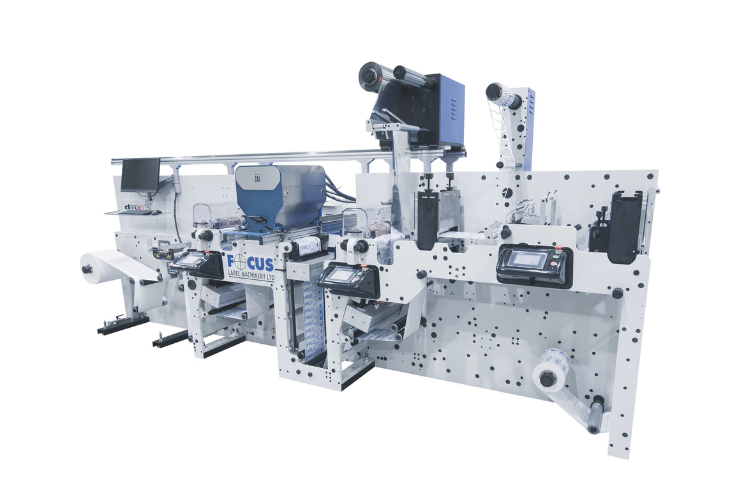

The versatile d-Flex digital hybrid press incorporates the latest HiQ 1800dpi high-speed, full-colour Konica Minolta inkjet technology (CMYK + W), which has been cleverly integrated into the existing Reflex servo press with in-line UV or LED flexo print heads, die-cutting, slitting and rewinding. High quality variable images can be overprinted in perfect register with UV or LED flexo ink, then converted & rewound – in a single pass with speeds up to 60 metres per minute. The latest e-Flex twin servo flexo press with automated pre-register functions can be specified with multiple drying options, including UV, LED, infra-red and chill rollers. The dual servo system provides single touch set ups, with minimal waste for conventional printing and can be combined with a digital module for variable data, text & images. The touchscreen HMI operator controls provide a fully programmable digital platform, plus storage of job details for future retrieval and are said to make the e-Flex, the most effective, affordable servo-driven flexo / digital combination press in the marketplace today.

The e-Flex incorporates top-loading print cylinders and quick-change print cartridges to reduce downtime and set-up wastage. A choice of ultra-efficient interstation drying systems enables much higher press speeds. The short web-path allows for a compact design, whilst still maintaining good accessibility for the operator and plenty of space for optional equipment. A rail system is available for overhead press options, including delam/relam, rotary cold foil transfer, silk screen, turn-bar, and multi-layer re-register laminating.

d-Flex

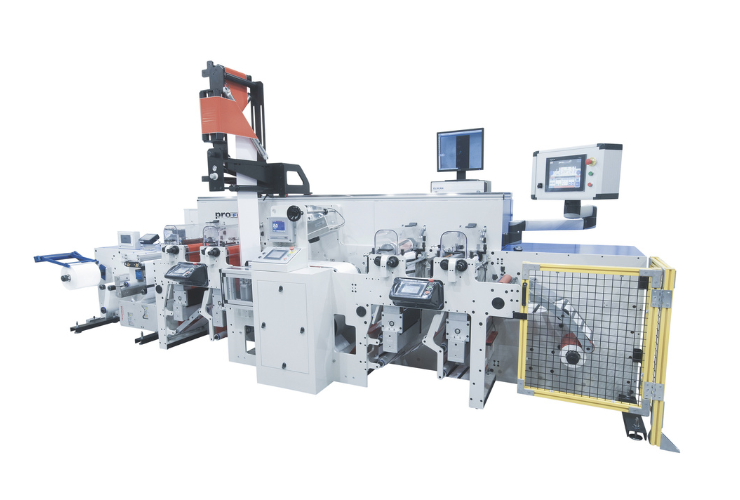

The ever popular Proflex SE model is a fully servo driven, modular press available with print widths of 250mm and 330mm. Several different drying systems are available, including full UV, LED, Infra-Red – or combination drying systems, with optional chill rolls for heat sensitive substrates. The open architecture design of the print stations enables easy loading of ink cartridges & print cylinders, whilst interchangeable print cartridges can be partially or fully unloaded and exchanged, in order to maximise productivity and minimise downtime. Bearer rings are incorporated into the print cylinder assembly, to guarantee accurate print impression settings, regardless of substrate.

Print cartridge assemblies can be cleaned off press, allowing the operator to maintain uninterrupted production. As well as flexo print heads, there is also a facility to accommodate a full colour or mono-colour digital inkjet system, for short run & variable data requirements.

The Proflex SE benefits from touch screen HMI operator interface panels, servo assisted control for all press operations, fully programmable digital platforms, plus storage of job information for future reference. The new features have decreased set up time and material wastage, resulting in reduced downtime and higher productivity. The operator can control all aspects of press operation, from any of the HMI touch screen control panels and can store job information for future retrieval on repeat orders. Print modules incorporate Digital Drive technology, reducing mechanical register errors and providing greater control over a wide range of substrates.

pro-Flex

Optional automatic print register control can easily be integrated into the servo press, to assist with print registration on difficult substrates. Also, the modular design of the system means that future addition of extra print heads & other optional equipment, including digital print engines is easily facilitated.

In addition, a rail system can be mounted along the top of the press, to allow optional overhead press equipment to be easily transported to the required position. Options such as turn-bar, delam-relam, cold foil, laminating, waste rewind turret, scanner systems, etc – can all be rail-mounted. Heavy duty, servo driven die cutting units with removable anvils are provided for converting a range of substrates from film to 300gsm board.

re-Flex

A non-servo model, Proflex E with the same open architecture print head design is also available.

For more details of FOCUS equipment visit: www.focuslabel.com

Contact: admin@focuslabel.com

This article is an advertorial; the featured company created the wording and paid for its placement. It has been checked by Whitmar Publications to ensure that it meets our editorial standards.