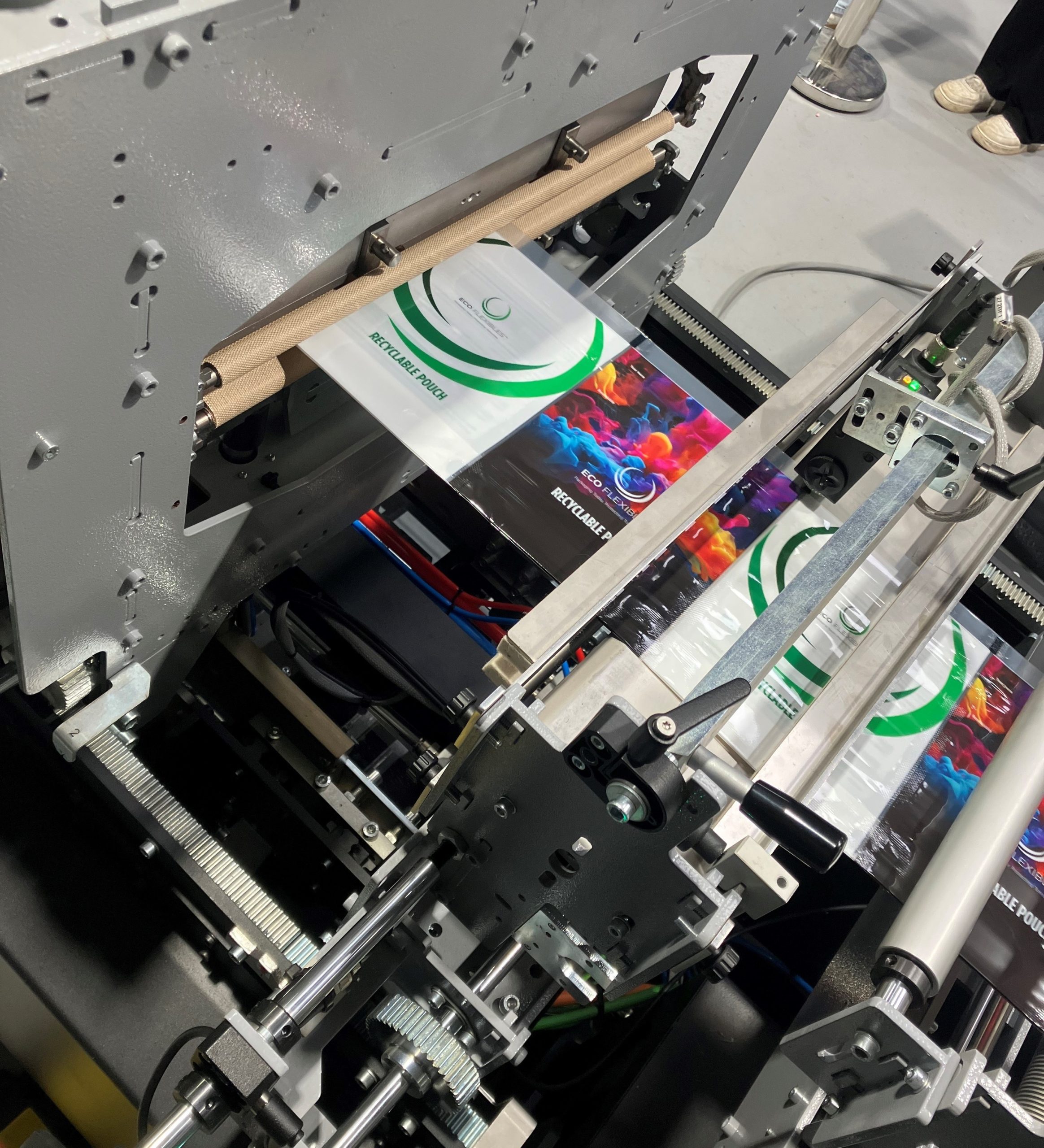

Recyclable flexible packaging producer Eco Flexibles has increased its capabilities with the installation of a second Karlville Swiss KS-SUP-400-D pouch machine following the success of its expanded product range.

The installation of the pouch machine at its new production site comes less than a year after Eco Flexibles first invested in establishing its pouch range.

In January 2024, Eco Flexibles installed the first Fujifilm Jet Press FP790 inkjet digital flexible packaging press outside of Japan at its new production facility. Due to high demand, the packaging specialist ordered a second in June with installation completed in September. Now with two Karlville Swiss KS-SUP-400-D pouch machines added to its offering, it has been a year of growth and investment for the Northampton based business.

David Smith, general manager at Eco Flexibles, stated, ‘Pouches are one of the fastest growing packaging formats, as our success demonstrates. Just 10 months on from our first install, due to the high demand we are experiencing, we are happy to announce the installation of our new Karlville Swiss pouch machine. It is a true packaging titan, giving us the ideal combination of speed, agility and quality that allows us to react quickly to our customers’ needs, marking us as a responsive, future-ready packaging partner.

David Smith, general manager at Eco Flexibles, stated, ‘Pouches are one of the fastest growing packaging formats, as our success demonstrates. Just 10 months on from our first install, due to the high demand we are experiencing, we are happy to announce the installation of our new Karlville Swiss pouch machine. It is a true packaging titan, giving us the ideal combination of speed, agility and quality that allows us to react quickly to our customers’ needs, marking us as a responsive, future-ready packaging partner.

‘Due to our significant investment and growth, 2024 has seen us establish ourselves as one of the few packaging suppliers in the UK that can produce and supply fully recyclable mono polymer and paper-based pouch packaging in-house. With a wide range of design options including high barrier performance, zippers, tear notches and euroslots, and finishes available in gloss, matte, white, and metallics, it’s clear why Eco Flexibles is becoming a packaging powerhouse in today’s circularity-centric marketplace.’