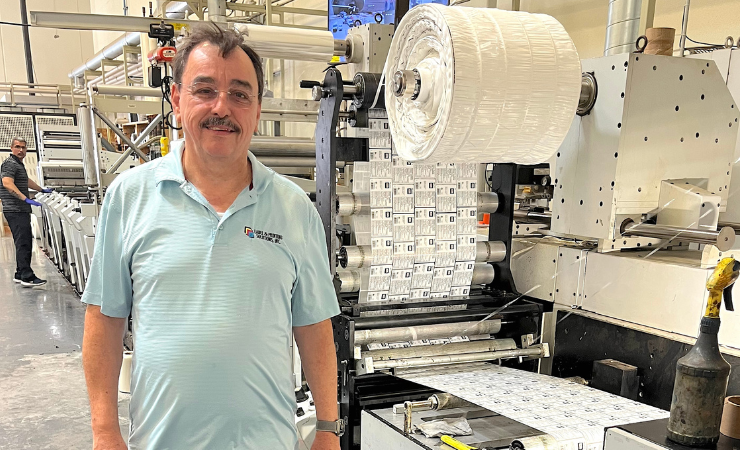

Phoenix-based Label & Printing Solutions, the US arm of Etiquetas e Impresiones de México, has invested in a 20in 11-colour Performance series P7 flexo press from Mark Andy to handle its pressure sensitive label work.

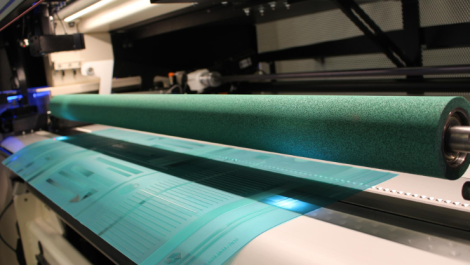

As stated by Label & Printing Solutions, around 20% of its label output is film, however 35% of the total business is packaging produced with PET and BOPP, a side which is the fastest growing for the company. Ricardo Stone, co-founder and general manager of the company, explained, ‘We laminate PE and BOPP in-house to produce pouches. In Mexico, we do it offline but have perfected a technique here with solventless adhesives to laminate online on the Mark Andy P7 – it’s tricky and requires accurate control of a counter-rotating anilox, but it works well and allows us to start and stop without having to clean-up the machine.’

The decision to invest in narrow web technology rather than wide web CI is supported by the company’s 12% year-on-year growth, said Mr Stone. He added that the company isn’t interested in ‘mega-run’ work, as typically, customers ask for 10,000 to 15,000 pouches – another reason for the investment in the P7 flexo press.

Label & Printing Solutions has used a variety of Mark Andy flexo presses over the years, from 830, to Scout and 2200 models up to Performance series P5 and P7. Currently, the company has nine Mark Andy presses in daily use, eight in Mexico and the latest 11-colour P7 in Phoenix.

Speaking for Mark Andy, sales manager for Latin America John Vigna, commented, ‘It’s always an honour to support a longstanding customer like Ricardo, especially with his pioneering spirit that allows him to make such creative use of Mark Andy technology to grow his business. I’m looking forward to introducing him to the raft of new developments that we exhibited at the recent Labelexpo in Chicago, which I’m sure can feature in his future plans.’