Soma, manufacturer of flexographic printing machinery, will host an open house on 20 November 2024 which will focus on automation, anilox management, and printing on tubing substrates, at its headquarters in Lanskroun, Czech Republic.

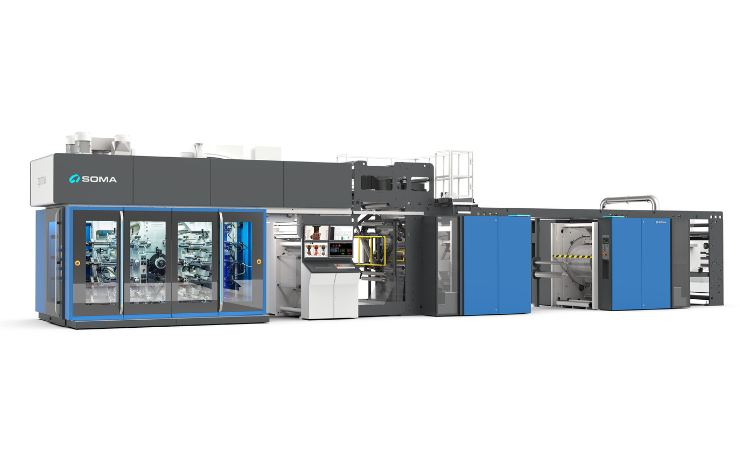

Attendees will be able take part in presentation sessions exploring automation and artificial intelligence, and how it may combine to ‘revolutionise’ flexo print quality, efficiency, and sustainability. Additionally, the event will provide visitors the opportunity to witness demonstrations of the Soma Optima2 flexo press, featuring the latest version of its anilox management and enhanced automation; the Soma S-Mount plate mounter; and the Soma Optima press with TubeTech technology, which is being introduced at the open house.

Optima TubeTech is a ‘specialised’ flexographic press created to handle the challenges of printing on tube and casing materials, ensuring precise, high-quality print. This technology allows for edge-to-edge printing on tubing substrates, delivering front-to-back side registration, explained Soma.

The event will also be an opportunity for Soma to showcase its ‘advanced anilox management system’, which it says is a revolutionary way to guarantee consistent, high performance for every anilox in a printer’s inventory. It has been designed, says Soma, to help flexo printers maintain peak anilox efficiency and quality, ensuring a company’s flexographic printing process remains reliable.

Petr Blasko, Soma marketing director, said, ‘This year has been an exciting one for Soma. We developed and launched new technologies at drupa that truly impact the productivity and quality of flexo printing. Our open house will give us another opportunity to show everyone how far we – and the industry – have progressed. I should also add that we are equally proud of Soma’s current facilities expansion. We look forward to showing everyone the pride we have in our first-class manufacturing operation.’