Heidelberg and Solenis, manufacturer of specialty chemicals, have collaborated to develop a cost-effective process to integrate barrier coatings for fibre-based packaging directly into the existing roll-fed flexo printing process with Heidelberg’s Boardmaster web flexo printing machine.

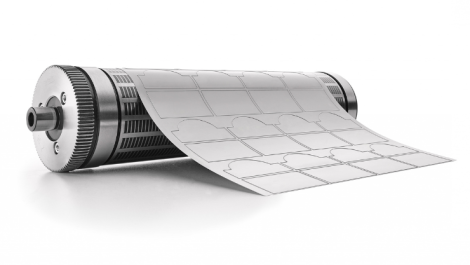

David Schmedding, chief technology and sales officer at Heidelberg, said the growing demand for sustainably produced, cost-effective, recyclable and compostable packaging makes flexible paper an area of importance for the company, one which the collaboration with Solenis will support. He added that the Boardmaster, boasting a production speed of up to 600m/min, is ideal for this market.

An area addressed through the collaboration is the quality and safety of flexible paper packaging – with barrier coatings playing a ‘key role’. To improve this, the companies have identified areas of focus, including optimally coordinating the individual components of the Boardmaster, the chemical composition of the Solenis barrier coatings, and a reduction in plastic use to environmentally friendly alternatives with improved barrier functionality. The overall package, said Heidelberg, should enable customers to expand their application range in the flexible paper sector with improved barrier functions that are cost-optimised, reusable, recyclable, renewable and compostable.

William Kuecker, senior director of strategic marketing at Solenis, commented, ‘Packaging companies are under increasing pressure to optimize processes while meeting ambitious sustainability goals. Our partnership with Heidelberg pushes the boundaries of what is possible for paper packaging manufacturers. With the combination of state-of-the-art printing technology and innovative, high-performance specialty coatings, packaging manufacturers can increase their operational efficiency and product performance while meeting the growing demand for sustainable products and processes.’