Koenig & Bauer (K&B) has teamed up with Tessitura, software developer within Steuber group, to bring levels of flexibility, efficiency, and transparency to production processes through the functions available in K&B’s myKyana portal – creating an open, interconnected production environment.

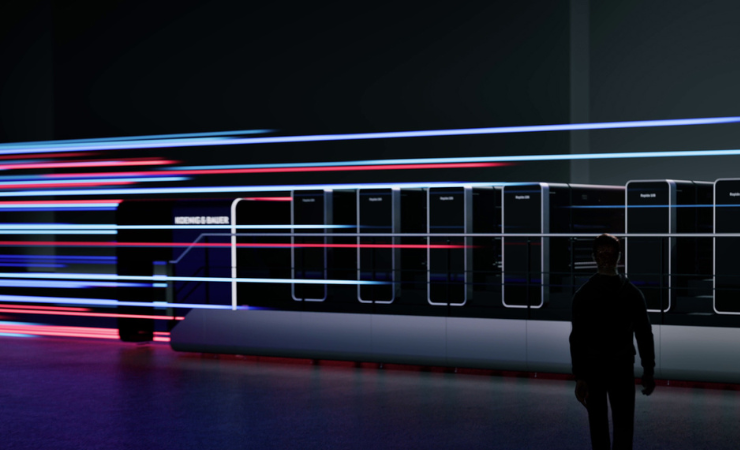

The myKyana portal, K&B’s digital platform, designed to streamline and enhance every aspect of the production process, now allows the seamless integration of third-party machinery. Two components of the myKyana portal are Kyana Assist, an AI-driven chatbot – soon to include AI-powered data analysis – which offers instant technical help, providing detailed, machine-specific guidance; and Kyana Data, a performance dashboard tool offering real-time monitoring, predictive maintenance and an ‘intelligent’ benchmarking tool.

With the integration of Tessitura’s Odeon platform – Odeon Worker and Odeon Connect Box – into the mKyana portal, K&B can go beyond isolated solutions, contributing to a more connected, efficient, and future-ready production environment for all customers, said the company. The platform is designed to connect all printing and finishing machines within a company, regardless of equipment manufacturer, whether modern or classic, and across single or multiple sites.

As a result of the collaboration K&B have summed up the keys benefits for customers: increased transparency, bringing all production data into a centralised platform, allowing users gain a comprehensive view of their operations; cost savings, as the ability to integrate and automate processes across different machines reduces redundancy and cuts down on manual interventions; and flexibility, as users can continue to leverage their existing equipment while also preparing for future advancements – myKyana’s open architecture ensures that new technologies can be easily incorporated, protecting investments in the long term.