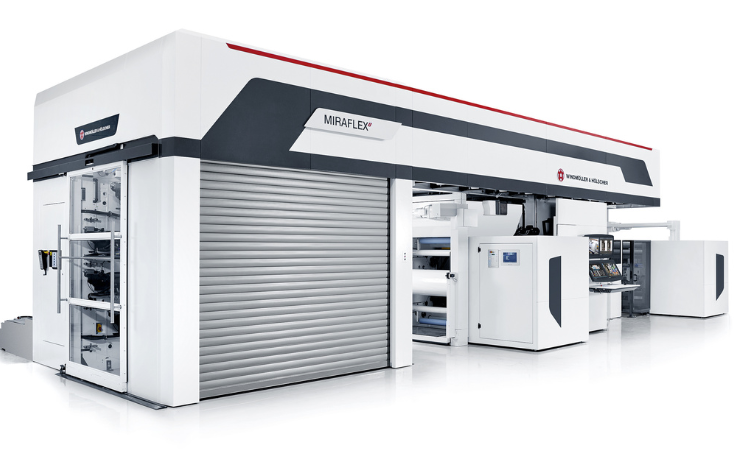

Coveris has announced a new £3 million (€3.49 million) investment in wide web flexo printing and converting technology, with a Windmöller & Hölscher Miraflex II press due to become operational at its Burnley, UK site by this September.

The investment adds to Coveris’s ‘HD print’ offering, contributing to the standardisation of ‘advanced quality flexo’. The new eight-colour press is equipped with a 100% inspection camera system for runs of up to 500m/min, as well as automated set up, changeover, drying and wash-up technologies.

In addition, Coveris believes the press will support its ‘No Waste’ vision, with a claimed 10% reduction in energy usage, alongside material, make-ready and ink savings.

The company has made further investment in its specialist conversion capability to go alongside the new press, including slitting capabilities to ‘maintain workflow and supply efficiencies’. It is also trialling a ‘nextgen’ specialist plate making material that it said supports its HD print offer.

Steven Hinchly, managing director of Coveris’ UK Flexibles business, commented, ‘This latest investment allows us to deliver leading quality, more efficiently and sustainably than ever before for our customers, whilst also futureproofing our business for further expansion into new and existing markets through our commitment to best-in-class print.’