New flexo plate technologies and software upgrades have been among the advances announced at drupa 2024.

From Asahi Photoproducts comes from the AWP-CleanFlatMedium plate, which it says is designed for improved ink laydown on rough substrates such as uncoated papers and recycled films. It is a medium hardness, water-washable Flat Top plate that can be used with solvent, water and UV-based inks. Also new is AFP-NFT, which is an upgrade to Asahi’s BFTK plate. It is a solvent-wash Flat Top plate suitable for wide web flexible packaging films, paper and label substrates. Both plates feature the company’s CleanPrint technology, engineered to ensure all ink is transferred to the printed substrate, and thereby reducing press stops for plate cleaning.

Miraclon has given a ‘soft’ launch to Flexcel Prime – the next generation of its Flexcel NX plate technology, optimised for LED exposure (and therefore shorter exposure times), and formulated for cleaner and longer running on press. This is currently in testing with some flexo printers in the US and Germany. ‘It’s looking good,’ Miraclon’s chief marketing officer Emma Weston told FlexoTech. ‘Ultimately, we think everyone will want to move from the current Flexcel NX plate to Flexcel Prime. It is practically a drop-in but with extra benefits. There will be another few months with the testing as we make sure it performs well in commercial production.’

On the DuPont stand, the discussion was around Cyrel EFM, a new thermal flexo plate for the Cyrel Fast platform, capable of use with a range of paper grades, and Cyrel Lightning LSE, a solvent plate that is optimised for LED exposure, as well as being designed for better ink transfer to rough surface substrates. The company has also reintroduced its smaller format 1000 TD to the Cyrel Fast processor line, incorporating the same technology as the 2000 TD and 3000 TD models, and has announced the launch of Cyrel University – a new online video-based flexo training program, taking users from beginner to advanced levels, and incorporating platemaking basics, optimisation and process control.

Fujifilm has completely rebranded its narrow web flexo ink range as CuremaX, and with its LuXtreme LED-UV curing technology developed with IST Metz, claims that it is the only company supplying both the inks and the LED curing. The technologies are optimised to work alongside each other, but alternative inks and curing systems can be used in either case. The CuremaX range includes conventional UV and LED-UV inks, as well as a dual cure InDirect Food Contact (IDFC) ink and a conventional UV IDFC ink.

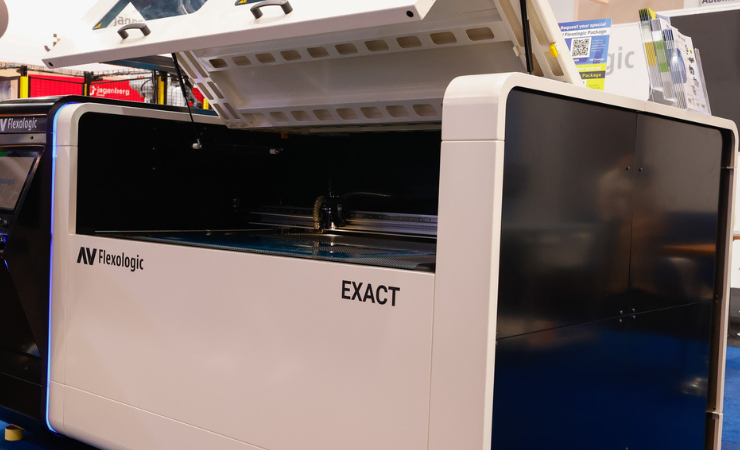

A new product from AV Flexologic is the Exact laser-based flexo plate cutting machine – the first of its kind, according to the company. As well as providing highly accurate laser flexo plate cutting in an enclosed space, with almost no operator interaction (therefore eliminating the risk of injury), it can engrave unique plate identifiers on the front or back of the plate, enabling traceability of plates and plate usage. The company said this was attracting a great deal of interest at drupa. Also new and on the stand were the SAMM 3.0 plate mounting system, which AV says is twice as fast as its predecessor, featuring a new design for high safety standards and simple operation, and the latest entry level MOM DDS 3.0 system, which also gives a speed bump, up 20% on its predecessor, as well as features for easier plate mounting.

XSYS has been showcasing its latest range of sleeves at drupa – the rotec eco series, which incorporates renewable resources and increased recycled content – and introduced a range of compressible accessories such as end plates, inner rings and notches, designed to absorb forces during handling to protect sleeves from damage. There is also a new structured sleeve surface for flexo printing with rotec sleeves, allowing air bubbles caught under mounting tape to escape more easily.

Moving into software, Hybrid Software reports that its Packz PDF editing suite for labels and packaging is heading for the cloud, meaning that operators will not require a powerful workstation to run it. This is expected to be live from the end of the year. Hybrid’s ColorLogic colour management, which enables colour matching between different presses and indeed different print technologies, is now integrated with its CloudFlow workflow automation suite. Hybrid said this new integration means that ColorLogic can potentially be put in the hands of front office staff, helping at the quoting stage. Hybrid’s Capture 3D technology is now integrated with Packz and iC3D packaging design and visualisation workflow. Capture 3D enables fast and precise grid creation and artwork distortion for wrapped shrink sleeves, die-formed metal cans and threaded bottle caps, making it possible to use the entire container for brand or marketing purposes.

eProductivity Software unveiled a new print MIS product at drupa, though Nubium is not aimed at the packaging and label sector. The company claims the software will ‘redefine print management’ for small and medium sized commercial printers. The cloud-native product contains a range of tools such as advanced estimating, inventory management, scalability, and integration with web to print and accounting packages.

Another MIS supplier, Sistrade, has been showing version 14.0 of its packaging and label platform. The new version includes a range of improvements for flexible packaging, corrugated cardboard, labels and extrusion, such as support for ‘quintuplex’ products – those with five layers of lamination – and a new way of estimating labels based on processes.

The drupa expo continues until 7 June. This story may by updated in due course.