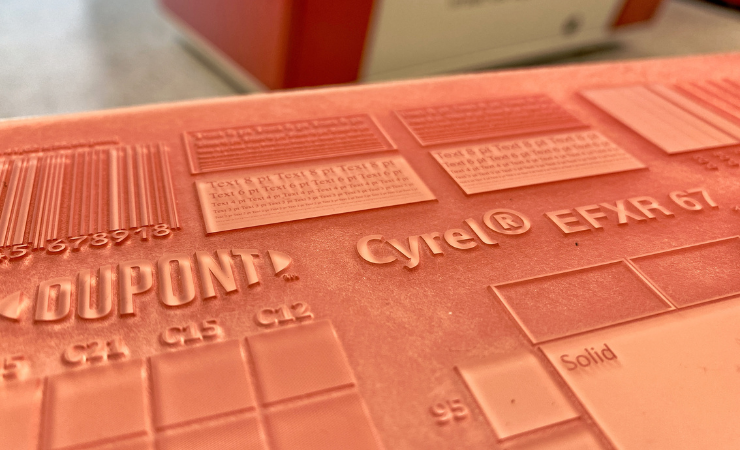

DuPont is celebrating the 50-year anniversary of the Cyrel brand, having introduced its first such photopolymer plate to the flexographic printing industry in 1974.

Tucker Norton, global business director for DuPont Cyrel flexographic solutions, stated, ‘This is an extraordinary moment for DuPont and the entire Cyrel team. Throughout this journey, we have brought countless innovations to the market and have always prioritised developments in collaboration with our customers.’

Examples of success, outlined by the company, start from the 1990s when DuPont introduced the Cyrel digital imager (CDI). This allowed prepress teams globally to migrate from an analog workflow, to a modern, digital ‘computer to plate’ workflow.

In 2000, DuPont introduced a thermal workflow, the Cyrel Fast system, which allowed flexographic plates to be processed without the use of chemical solvents. This innovation reduced plate-processing time and had environmental benefits, which included a 53% saving in greenhouse gas generation and a 63% reduction in non-renewable energy consumption.

In 2015 the company introduced the Cyrel Easy plate, the first plate with a flat top dot directly in the plate.

Later, DuPont introduced Cyrel Easy-R plates, building on the Cyrel Easy platform, further advancing performance on press, and making the plates even easier to handle in the plate room.

Cyrel Easy brite screens followed in 2018, designed to optimise ink laydown in high-volume ink transfer applications, typically seen when printing a white undercoat, or solid areas with spot colours.

On the corrugated side, Cyrel DLC plates launched in 2019. Developed specifically for printing on recycled low top liner weight cardboard, this plate addressed a need to achieve quality printing and less board crush.

More recently, DuPont launched the Cyrel Lightning Plate series for both the solvent and thermal platemaking workflow, optimised for a UV-LED exposure.

Reflecting on this milestone, Mr Norton commented, ‘We are committed to continuous innovation and look forward to perfecting flexography together with our partners and customers in the next decade.’