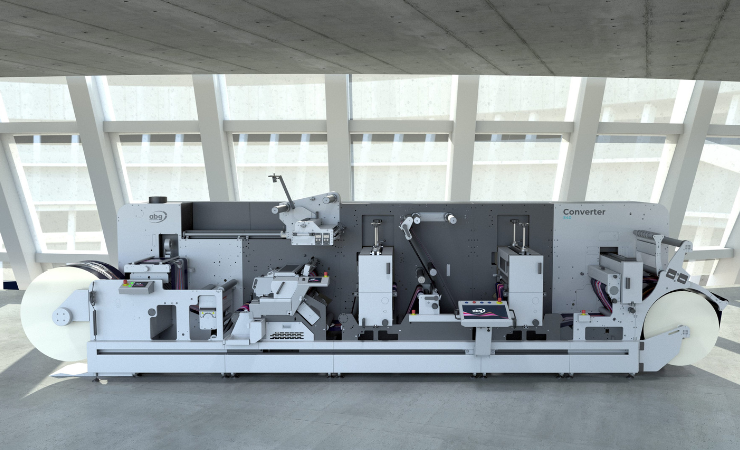

Finishing equipment manufacturer AB Graphic International (ABG) has announced details of its latest Converter system, a highly modular platform that can achieve running speeds of up to 250m/min.

This fourth-generation machine has a heavy duty die head, which ABG says reduces heat generation during die cutting, and results in consistent air gap performance with thin liners and precision die cutting. It has an extended rewind and waste rewind roll capacity of up to 800m (previously 700m), and has a dual-frame unwind feature and offset brake that makes loading and unloading easier, helping to improve operational efficiency, especially for rolls smaller than 200mm.

In addition, the built-in flexo technology of the Converter sets ‘new standards’ in print quality, registration accuracy and speed, said ABG. Other features include expanded camera placement options, including before or after stripping, and a compact footprint to help converters make efficient use of their space.

It can run roll to roll, roll to finished product and roll to sheet, with or without ABG’s non-stop technology on the unwind or rewind. A wide range of ABG modules can be retrofitted, making it customisable with evolving demands.

Matt Burton, ABG’s global sales director, commented, ‘The new Converter Platform is meticulously designed to minimise downtime, optimise workspace, and reduce the reliance on highly skilled operators. It represents a future-proofed investment that can adapt to evolving needs, keeping businesses at the forefront of the converting industry.’