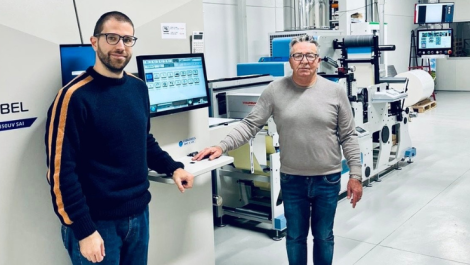

Corrugated board producer Klingele Paper & Packaging Group has invested in a new ChromaCUT X Pro cutting system from Koenig & Bauer Celmacch, with production start-up planned at its plant in Delmenhorst for July 2024.

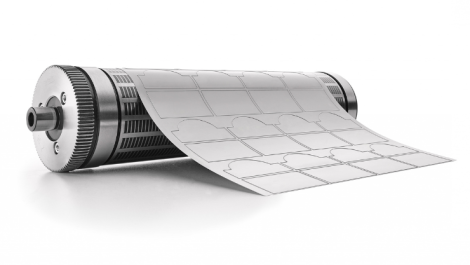

This is the third such machine for the German-headquartered company – the second at Delmenhorst, with one at Werne. It is highly automated and, for the first time for Klingele, is equipped with a pre-settable rotary die-cutter. The Group says the new ChromaCUT X Pro will help it fulfil orders more efficiently.

Because of the pre-settable rotary die-cutter, the die-cut cylinder that is not in production can be set up during running production. At the end of the job, the die-cut cylinders can be changed fully automatically and within a few minutes. All units – from the pre-feeder to the palletizer – are completely networked, with production data automatically transferred to the machine. Automation features include Easy Job Change.

Patrick Ginter, plant manager in Delmenhorst, commented, ‘The simple, intuitive, automatic and ergonomic operation of the machine is a significant relief for our operators. As a result, follow-up orders can be prepared more efficiently, and we can increase the production and work even more efficiently.’