Mexico-based printing company Eticom has invested in a second HF330 standalone hot foil unit from GM to increase efficiencies and speed up delivery times of embellished labels.

Founded over 22 years ago, Eticom is a label and packaging printer headquartered in Mexico City. Offering flexo and digital printing, the company is one of the largest label printers in the Americas with over 200 staff spread across sites in Mexico and the US.

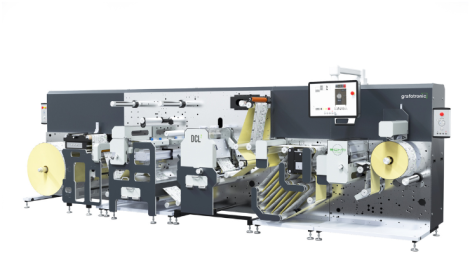

Whilst already using GM finishing technology, the decision was made to invest in a second standalone hot foil unit from the Danish manufacturer to increase efficiencies and speed up delivery times of embellished labels.. The new GM HF330, which can work either inline with a digital press or offline as a standalone machine, is enabling Eticom to apply hot foil stamping and embossing in a single pass. A 50-ton flatbed hot stamper with multiple foil streams allows different colours to be applied and effects to the printed on labels to enhance their shelf appeal.

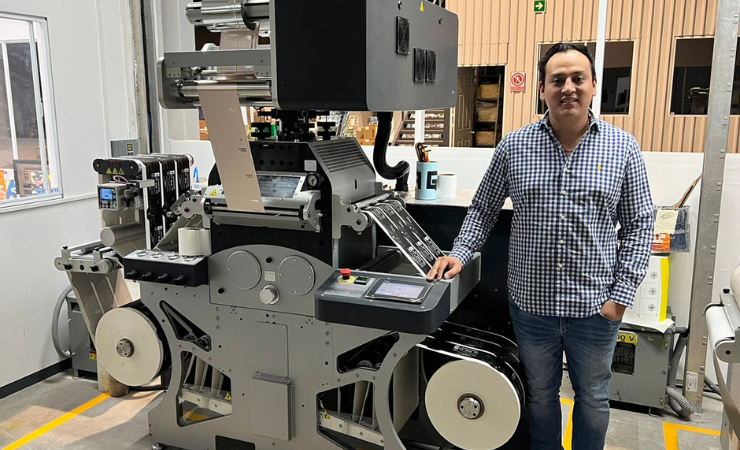

Carlos Ramirez, production director for digital at Eticom, commented, ‘We are always looking to improve our production capabilities by optimising time, cost and quality. Now with a duo of GM HF330 standalone hot foil units, we can not only add maximum value for our label customers with high-quality hot foiling and embossing, but also deliver the products much faster.’

Jos Kabouw, business development manager for GM in Latin America said, ‘I’m very pleased that Eticom’s first HF330 was such as success that the company has decided to add a second unit to its existing line-up of GM finishing equipment. Having foiling and embossing in one compact and robust tool is a massive advantage that also benefits Eticom’s customers by adding high value at a very cost-effective price point.’