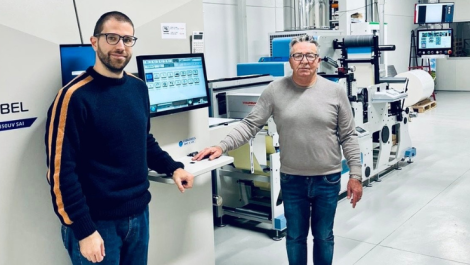

Grafisk Maskinfabrik (GM) has launched the DC350Flex+ wine and spirits line for premium embellishment of labels, claiming the new line will give label converters a more profitable way to enter luxury markets.

The new 350 mm-wide finishing line offers a combination of technologies in a single pass, featuring flexo varnish unit, hot stamping for foiling and embossing, screen-printing, and 130 m/min rotary die cutting as standard.

GM’s CEO Uffe Nielsen said, ‘We have learned in the past few years that even when times are tough, consumers are still prepared to pay a premium for a little bit of luxury to treat themselves, which means that brand owners are looking for ways to add a luxury look to their labels. The cost, however, is always the main factor, so label converters need high-quality machinery with high productivity that can deliver without breaking the bank.’

Running at a speed of 70 m/min, the machine enables precision embossing and foiling in one process, saving time and space. It also comes with an integrated foil saver to reduce the waste of costly foils. Other standard features include the die-cutting speed of 80 m/min in semi-rotary mode and 130 m/min in full rotary. The flatbed screen-printing unit contains a variety of varnish effects or high impact screen colours.

More modules, such as digital varnish and laser cutting, can be added either from the start or retrofitted at a later date to expand the reach.