Windmöller & Hölscher (W&H) has launched the Vistaflex II, a new wide-web CI flexographic press with upgrades for enhanced performance, improved print quality, and easy job changeovers.

W&H launched the original Vistaflex in 2008, aiming it at a small segment of high-end printers in the flexible packaging market who required a workhorse wide-web press that could run jobs 24/7 at speeds of up to 800 m/min.

Specific features of the press included the ability to prepare and store four additional jobs while the press was running and to execute fully-automated changeovers with two high-speed robots by pressing a button.

The company has since upgraded and redesigned its flagship and fastest press, as Hermann Veismann, general manager for printing and finishing, explained. ‘When we started conceptualising how and what to update on the Vistaflex, we realised, what an exceptional press it still is well over a decade after its inception. To make the press even better for our customers, who run these machines extremely hard over prolonged periods of time, we started with improving the bearing system to increase stability and print quality.’

Dr Holger Kreilkamp, team leader product management, added, ‘Automation and assistance systems are making a dramatic difference in production efficiency, by shortening changeover times, minimising waste, and making the process more straight-forward and easier for press operators. With this top of mind, we integrated W&H systems directly into the Vistaflex II.’

Specific upgrades include an improved CI drum cleaning system, which is particularly beneficial for paper and non-woven products, Easy-Set and Easyreg for automated impression and register setting, W&H Vision for web monitoring and defect detection, and the Turboclean Advanced E, which is W&H’s resource-efficient, award-winning washing and inking system.

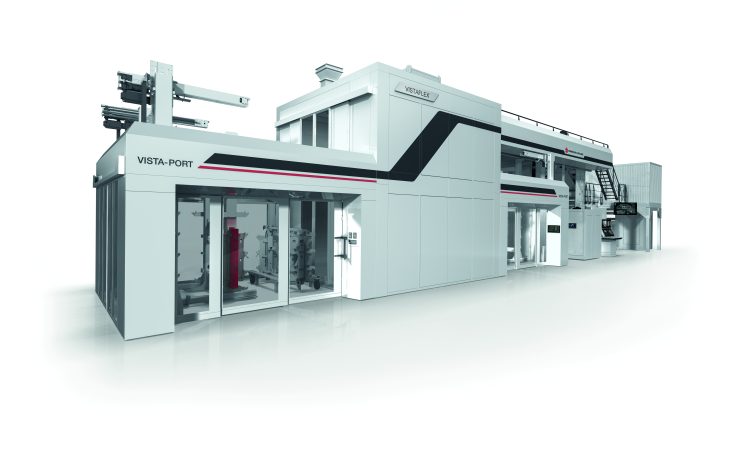

Also available is the Ruby IoT platform. Coupled with Connect 4 Flow the system creates a direct link between a customer’s ERP system and the press, which allows jobs data to be sent remotely for automated smart job queueing and optimised workflow. The Vista-Port, where prepared cylinders and sleeves are stored, then organises the integrated cylinder magazine automatically and prepares the necessary robotic changes. W&H believes that this concept is ‘unique on the market’ and says that it is designed to bring the future of autonomous printing closer.

In addition, W&H has developed the Filmatic II C winder to complement the press. The new non-stop, high-performance winder is available with an integrated slitting module.