XSYS has announced that it will be adding more staff and ‘proactively streamlining its offering for packaging print production,’ as it looks to develop its share of the North American market.

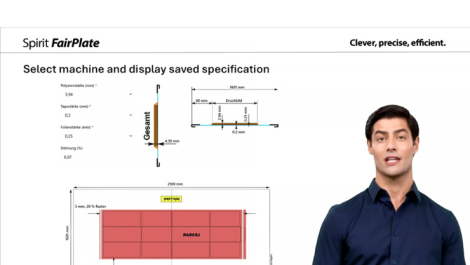

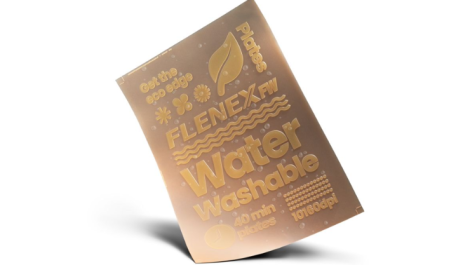

The prepress specialist, which separated from Flint Group earlier this year, supplies solutions for the entire breadth of the prepress process, from imaging and screening, through plates and platemaking right into the pressroom with adapters and sleeves. Specific products and brands in its portfolio include nyloflex flexographic solvent and thermal plates and equipment, nyloprint letterpress plates and equipment, nylosolv washout solvent, rotec sleeves and adapters, ThermoFlexX TfxX Imagers, ThermoFlexX Catena Plate Processing equipment, and Woodpecker surface screening solutions.

Managing director for plates, Eric Gibbs, who has worked at the company since 2013 and has more than 35 years of industry experience, said, ‘Customers are investing and reinvesting with XSYS, buying new more automated equipment, so they can maintain their productivity in spite of serious staffing problems and shortage of skilled workers. What they get is simply high-quality, consistent plates that will produce great flexo print for their customers.

‘We are now growing our dedicated team committed to providing the best possible sales and service offering in the market. The US and Canadian teams are seeing strong demand for XSYS imaging technology and platemaking equipment due to the high levels of automation they deliver, not only on quality, but also alleviating staffing issues and taking out any waste in the process.’

Dan Rosen, the company’s North American sales director, added, ‘With increasing cost pressures and supply difficulties experienced across the market, it is more important than ever to highlight our strong commitment to helping customers in everything they do.

‘Converters are challenged by demands for lower costs and better sustainability, while struggling to retain skilled staff and still maintaining high quality. We have best-in-class solutions for every segment of the packaging market that allow converters to be brilliant, deliver for their customers, and stay competitive in tough times.’