Springboro-based Trebnick Systems has installed a Nilpeter FA-17 to handle increasing customer demands for RFID-application.

Trebnick Systems is a long-time partner, having purchased their first Nilpeter press in the 1990s, when it developed a non-tear tag for durable markets that eliminated the need for laminated tags worldwide.

‘When we got into the label and tag market, we were too late to get any easy jobs. All the jobs we received were the jobs no one else wanted to do – uncoated poly material with process printing, adhesives that would not come off when applied outdoors in the middle of the winter, poly tags that stretch through 99% of the presses on the market, etc. The challenging start, however, is what gave us a leg up on the competition, and what positioned our team in the expert category,’ said Linda Trebnick, president of Trebnick Systems.

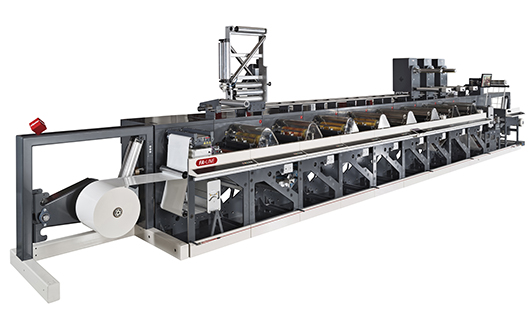

‘We already had the capability to apply RFID, but more and more of our customers are asking for it, and we needed to update our equipment to be able to handle those demands. As I mentioned, we already have Nilpeter presses and wanted to stay with them, so we went to Nilpeter, and together with Tamarack they came up with a press design for us that includes RFID-application and integrated labels,’ said Ms Trebnick.

‘Our first order on the press is a 750,000 feet long cast-and-cure hologram label. Being long-run and unique, plus being sheeted, makes it a perfect match for Trebnick to produce on our new press. We need the capacity to keep up with our current growth, and with the add-on unit from Tamarack we will be doing RFID, integrated labels, and high-quality colour work,’ Ms Trebnick concluded.