Lux Global Label based in Pennsylvania, USA, has invested in an FA-17 flexo press to increase operator efficiency and bring new products to the market.

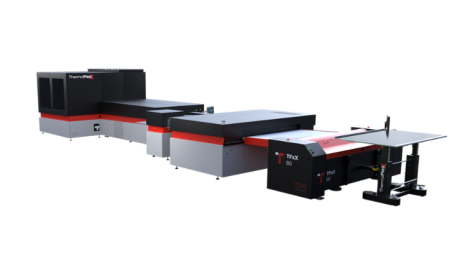

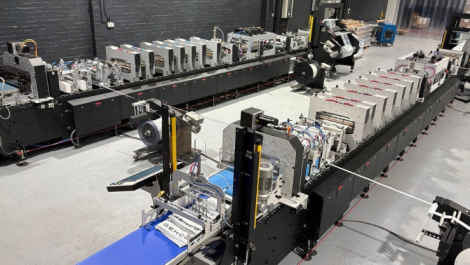

The 10-colour flexo press features a new vertical auto-locking mechanism which secures stability throughout the printing process, web-driven impression rollers with a special anti-slip surface treatment, and the new generation CLEANINKING system, which offers consistent density performance at all speeds.

‘Our ambitions with the new press center around two key areas – operator efficiency and product development,’ said Leslie Gurland, executive vice president global sales and marketing, Lux Global Label.

‘First, the press enables us to increase speeds and cut waste levels, which will allow us to improve lead times and remain cost-competitive in the marketplace. Second, this installation is a sign of our continued commitment to testing the limits and bringing new cutting-edge products to the market,’ she continues.

‘We have partnered with a company that developed a micro motion 3D-effect technology that requires ultra-precise printing and perfect registration. This can only be produced with the newest FA. The product has far-reaching possibilities both as a unique security feature for the healthcare industry, and as a visual showstopper for personal care products,’ she concluded.

The FA-Line is the most versatile flexo press on the market – designed to accommodate the printer’s ever-growing needs, and built around the modern print operator, with an intuitive user interface and fully mobile print controls. The FA allows printers to enhance the performance of their press with Value-Adding Units, Application and Automation Packages. All main components are produced in-house, meaning higher production quality and control. Nilpeter’s LEAN production flow and uniform facilities in Denmark and the US assure delivery worldwide.

”It is important for me to acknowledge all of the incredible employees of LUX who are considered essential workers, producing labels for much needed drugs, over the counter products, and hand sanitizers. They have come to work day in and day out and gotten their job done with a positive attitude. Luckily most of our customers have seen business grow during COVID, as have we, which has of course been a positive in these very challenging times. We have had to pivot and support our customers without in-person visits, through virtual sessions, meetings and press proofs, and only being onsite for mission critical projects.’ said Ms Gurland.

‘I am proud of a call which we received recently from an industry veteran – a credit both to us at LUX, and to our Nilpeter combination presses. The person was producing labels that were very similar to ones that LUX had produced in the past, and his customer wanted to achieve the same look as our labels. Unfortunately his presses were straight flexo and he could not succeed in matching the look we achieved.’

‘The label we produced used a white pearl gravure ink which gave a natural shimmer versus a grainy look. The purple vignette was produced in offset so it visually feathers into the white, where flexo printing would create a hard line. It was a huge compliment when this man, who has worked for some of the biggest and best label companies, said, “Your label is beautiful – I don’t know anyone in the United States that can match this”,’ Ms Gurland added.