Baldwin Vision Systems has unveiled its Defender inspection and defect tracking solution which uses self-learning algorithms and high resolutions to detect low-contrast defects.

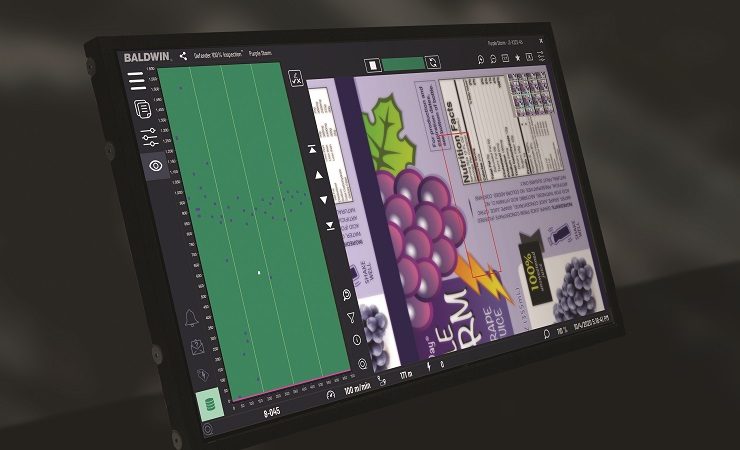

Specifically designed for wide web packaging substrates, the Defender 100% Inspection is the foundation for the company’s most comprehensive defect tracking solution. Defender Data Central and Defender Waste Manager combine to function as a seamless defect detection and tracking workflow.

The combination of technologies enables printers to easily deliver defect-free, perfect print quality to brand owners and print customers. Empowered with valuable production data and detailed print quality reports, printers can improve their processes and put more work through the press—reducing the need for additional presses or press time.

John Cusack, business development specialist for Baldwin Vision Systems, commented, ‘Print buyers are increasingly requiring 100% print inspection along with detailed print quality reports. The Defender technologies enable printers and converters to monitor and enhance their processes and directly improve their bottom lines. On top of that, knowing where defects are and having the tools to easily remove them greatly reduces the risk of returns, litigation, lost business, and a damaged reputation. The Defender workflow gives printers the ability to meet brand owners’ expectations, retain current customers, pursue new markets and win new business with a clear competitive advantage.’

Defender 100% Inspection uses advanced defect detection algorithms to quickly classify each defect, driving better print quality decisions. Self-learning algorithms monitor the capabilities of the press and automatically apply inspection tolerances to each job. Job settings can be quickly modified and saved. Manual fine-tuning makes it possible to reduce false or nuisance alarms by simply adjusting sensitivity levels for multiple defect types and different substrates. Modern, high efficiency, fan-cooled LED lighting delivers high intensity with greater image detail and low image noise.

Defender Data Central offers more intelligent print inspection by using the visual maps of each inspected roll. Quality control operators can analyse for defect distribution, count, and type. Out-of-tolerance areas are identified for removal, and job-based quality reports can be generated.

Defender Waste Manager can interface with rewinding, slitting, and sheeting equipment to automatically control when they stop/reject—allowing for fast and easy removal of defective material. Defect location data speeds up the converting process by allowing operators to fast-forward to the exact location of the defect within a roll.

‘Our advanced, data-connected workflow gives you the ability to make strategic decisions based on facts,’ said Mr Cusack. ‘With the tracking workflow, it’s possible to eliminate all defects from outgoing product, providing perfect quality to brand owners. It is also possible to make tactical decisions about which defects do and do not need to be removed, based on your customers’ specifications. This ensures maximum yield and maximum profitability—job after job.’