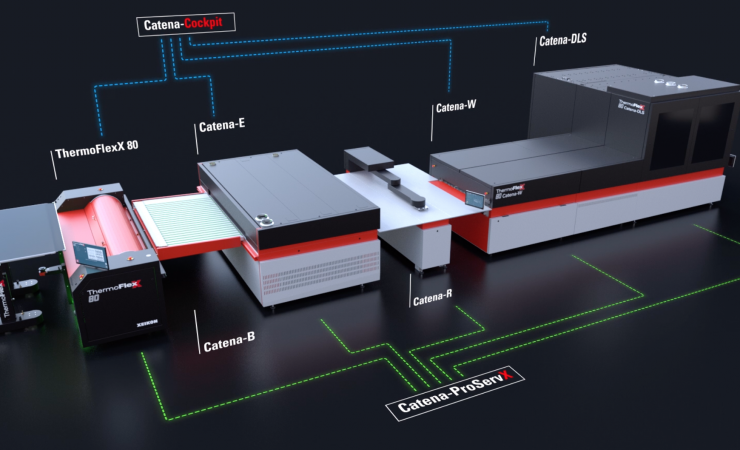

Flint Group has introduced the Catena-DLS module, the final link to Catena+, its fully automated and integrated flexo plate processing system.

The launch of the Catena-DLS module completes the processing line with 10 drying units, seven stacking positions, a light finisher and plate stacker combination.

The full Catena+ line includes Catena Cockpit reporting and Catena ProServX software for pro-active support and maintenance. It brings the whole chain together in combination with Flint Group’s ThermoFlexX Woodpecker surface screening software. Designed as an open system, this state-of-the-art plate processing system allows customers to produce flexo plates at the lowest total cost for every application.

‘We are proud to announce the Catena-DLS, the missing piece on our way to fully automated flexo plate processing,’ said general manager Uwe Stebani. ‘In combination with our ThermoFlexX imager, the recently released Catena-W and the Catena-E UV LED exposure, we provide a state-of-the-art, fully automated and integrated flexo plate processing system, which allows our customers to produce flexo plates at lowest total cost for every application.

‘In combination with our groundbreaking ThermoFlexX Woodpecker surface screening software and best-in-class Flint Group flexographic plates, we enable our customers to rival any other system in the market.’