DataLase has launched a new functional coating for corrugated packaging. WBF 6101 is a water-based flexo coating that extends the capability of the DataLase Case Coding solution to enable laser coding and marking of both white and natural kraft corrugated boxes.

A white-to-black laser reactive coating, WBF 6101 is an alternative solution to traditional labelling of logistical information onto corrugated boxes, aimed at helping brands reach their sustainability goals.

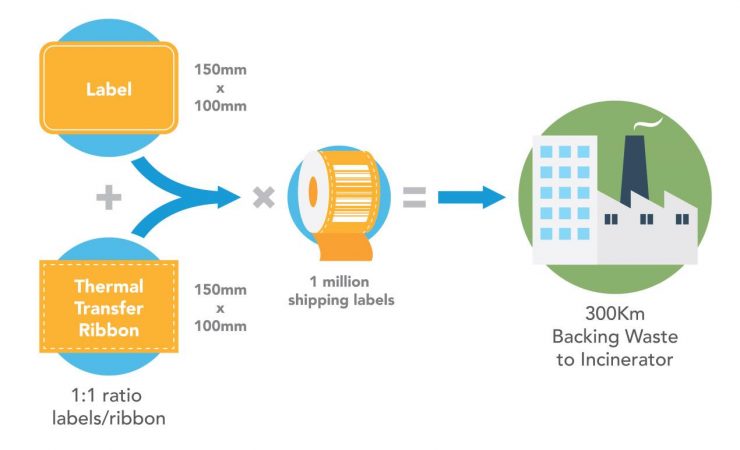

‘Packaging sustainability and single use plastics are front of mind for brands today,’ said chief sales and marketing officer Mark Naples. ‘With an ever increasing number displaying their commitment through publicising 2025 sustainability targets. We estimate that for every one million typical shipping labels used approximately 300km of unnecessary backing waste is produced.

‘If we apply this to a typical production environment, it equates to thousands of kilometres of backing and thermal ribbon waste being sent straight to an incinerator every year. The DataLase Case Coding solution creates significant operational savings for manufacturers, as well as contributing to brands packaging sustainability agendas.’

DataLase Case Coding aligns with circular economy initiatives, such as the UK Plastics Pact, by removing single use plastics from the production environment. It also brings additional environment advantages, including removal of inks and solvents from the fulfilment area, robust coding avoiding unnecessary waste, high coding throughput and operational reliability. Lasers require minimal preventative maintenance and servicing and no resulting hazardous waste disposal considerations.

Finally, the new coating creates high contrast, high quality, durable codes that do not smudge or rub off resulting in less product recalls and penalties from retailers for rework.