Global Packaging Solutions (GPS) has deployed Vetaphone’s corona technology across all three of its presses to overcome printing problems. The American firm, founded 14 years ago in North Carlolina, employs 15 staff and boasts annual sales in excess of $3 million.

GPS’ first press, a 10-colour 18 inch Comco Commander was installed in 1994, followed by a Mark Andy Performance Series P5 at the end of 2013. The 17 inch 10-colour line was installed with laminating capability to handle the majority of film work that the company produces, mostly BOPP, PE and PET. And it’s this specialisation in filmic substrates that makes the choice of corona treatment so critical.

‘We had an American system on the Comco, which initially worked well, but gave us arcing problems whenever it was humid, and cleaning meant virtually taking the unit apart in order to make it operational,’ explained founding partner Jim Anderson. ‘The treater on the second press was from the same manufacturer and proved to be even more problematic. After weekly troubleshooting calls with Mark Andy, they recommended we try Vetaphone technology. The end result is that we fitted a new Vetaphone VE1A corona treater and iCorona generator to the Comco and were so pleased with its performance that we replaced the nearly new American corona unit on the new P5 press with Vetaphone equipment too. We haven’t looked back since!’

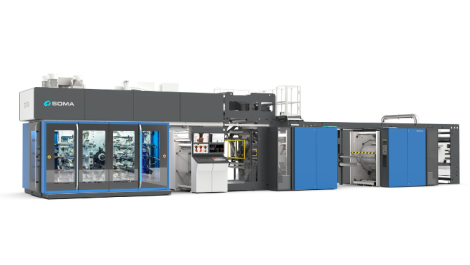

GPS has recently added a third press to extend its production capabilities. It’s a 10-colour 22 inch Mark Andy P7 that is set up for high speed water-based printing and has UV or dry bond lamination capabilities inline. ‘Of course, we specified Vetaphone technology,’ finished Anderson. ‘You need quality equipment to produce quality work!’