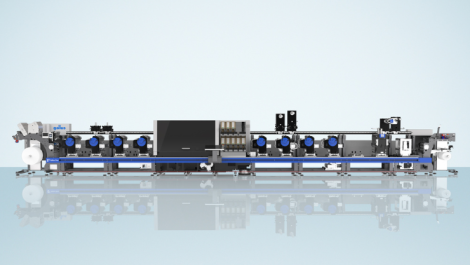

The new press is aimed at flexible packaging applications

German press manufacturer Windmöller & Hölscher is developing its first digital press for flexible packaging. Having done research since 2016, the company has chosen Xaar’s 5601 piezo printhead technology to drive the single-pass, inkjet machine.

‘We see a need in the flexible packaging market to use digital printing in addition to the established processes. This is driven by the need for faster time-to-market and very short order lengths,’ said CEO Dr Jürgen Vutz. ‘However, the application of flexible packaging has very special requirements, for example regarding the adhesion of the ink to the film. As specialists in this market, we bring expert knowledge to offer answers to these challenges. First, by continuously advancing the established processes, such as flexo and gravure printing, and second, by opening up the possibilities of digital printing for flexible packaging.’

‘The new digital machine will be characterised by higher quality and higher speeds, and opens up new possibilities in flexible packaging,’ added Sven Michael, head of the W&H digital team. ‘It includes the Xaar 5601 printhead, which achieves excellent print quality at high production speeds.’

Windmöller & Hölscher is the first OEM to publicly announce that its next generation of printers will be driven by the 5601. ‘This announcement is a significant milestone for Xaar,’ commented Doug Edwards, CEO at Xaar. ‘Windmöller & Hölscher is a major player in the flexible packaging machinery market and is renowned for placing innovation at the heart of its new product developments. I’m delighted that the Xaar 5601 has been selected for this new development on the basis of the printhead’s high performance.’

‘High availability and usability in daily use are our top priorities. Our goal is to go to market with a functioning and mature digital printing machine that delivers on the promises of digital printing for flexible packaging as well,’ concluded Dr Vutz.