(L-R) Alessandro Lucherini, printing specialist, Bobst Firenze; Nicola Mazzei, area sales manager Italia, Bobst Firenze; Alfonso Amoruso, owner, Alfa; Franco Buffi, production manager, Alfa

Italian label company Alfa has invested in Bobst M5X technology to increase label production capacity at its site.

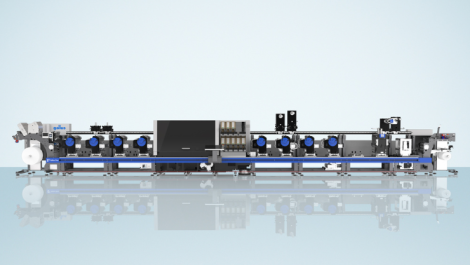

The Bobst M5X inline UV flexo printing and converting machine, which features a 430mm web width with multi-process inline units for the enhancement and die-cutting of labels, was installed at the production plant, based in the Marches region of Italy, in July 2018.

Owner, Alfonso Amoruso, commented, ‘The continuous improvement and updating of our equipment and processes is a focal point of our corporate mission. We invest in equipment selected for production flexiblity and the output quality our clients expect us to deliver.’

The company designs and prints reels of PSA labels, multi-layer labels, shrink sleeves and laminated composite structures for single serve sachets using low migration inks, primarily for the domestic market. With clients increasingly demanding technical applications, the range of options the new printer offers – including cold foil stamping, printing on adhesive, multi-page labels, screen printing and multi-station die-cutting – were of key interest to Alfa.

Mr Amoruso added, ‘The accuracy of the PrintTutor automatic register control system on the M5X is excellent and the job changeovers are fast, enabling us to profitably print jobs of varying lengths. Furthermore, the connectivity of the M5X suits our pressroom architecture of automation and production control.’