(L-R) Hubert Sampré, Miller Graphics, Philippe Desange, Kodak, Claude Vriet, Miller Graphics, Philippe Coulonnier, Miller Graphics

International image processing specialist for the packaging industry, Miller Graphics Group, has invested in the Flexcel Direct System for its Limoges plant. The company signed the deal at drupa 2012 and became the first pre-press company in Europe to invest in the technology.

Miller Graphics Group has 380 employees operating 13 sites in Europe and generates a turnover of €45 million. Its customer base comprises decision makers and packaging printers, which use flexo technology to print paperboard boxes, flexible packaging, notebooks, kitchen paper, labels and more. In France, the company operates from three sites, Limoges (Limousin), Beauvais (Oise) and Avignon (Vaucluse), and is the only pre-press company in the country to manufacture and directly engrave elastomer sleeves for flexo printing. It has a 140 strong staff and generates a turnover of 16 million EUR.

For managing director, Hubert Sampré, the decision to invest in the Flexcel Direct System was a relatively easy one. ‘We spotted the system at drupa 2008 and were impressed by its laser diode technology. We had the privilege of being chosen by Kodak to test the machine, due to our experience of engraving ITR (cylindrically shaped) sleeves for flexo printing. We’ve been testing the system at our Limoges plant for six months. We’re very happy with the very positive feedback from our customers, so we decided to make our purchase official at drupa 2012.’

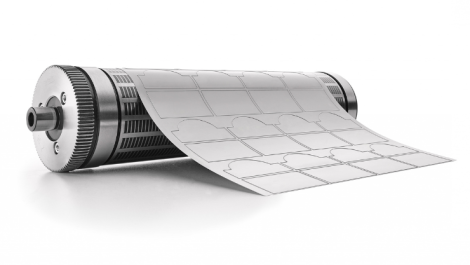

A complete, optimised end to end system that utilises engraver, workflow and unique media to drive improvements in quality and productivity, the Flexcel Direct System simplifies the sleeve manufacturing process, eliminates variations inherent in traditional flexo processes, removes the need for harsh solvents and is ideally suited to all forms of printing.

‘The elastomer sleeves are ready to use, which helps boost production speed by around 50%,’ added Mr Sampré. ‘Direct engraving removes the need for solvents and uses a powerful filter to neutralise particulates, making it a very environmentally friendly flexo system. We also like the fact the high power laser system is energy efficient, ergonomic and simple to operate.’

Mr Sampré has been particularly impressed by the print quality delivered by the system. ‘This engraver together with the dedicated Kodak sleeves produces a level of sharpness that we’d not previously seen. The print quality is equivalent to the best that can be achieved with digital flexo plates.’

Brands have quickly been won over by the attractive, high quality packaging. ‘As well as the quality, customers have been impressed by the greater consistency and shorter set up times. With a rising demand for these engraved sleeves, and a plan to push the technology in the flexible packaging and label segments, we had no hesitation in finalising the purchase of the Flexcel Direct System,’ concluded Mr Sampré.

www.kodak.com