Annemarie Rhodes, managing director

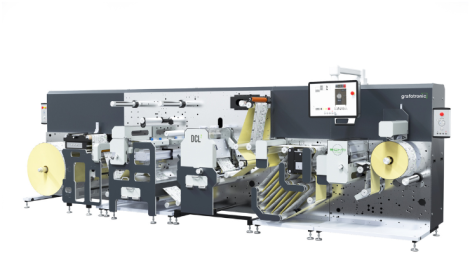

Two new systems will deliver improved productivity in the digital converting and the flexible packaging-finishing sector both from Bar Graphic Machinery.

Joining the manufacturer’s portfolio is the 160 mpm Elite Digiflex full servo flexo die cut to re-register slitter rewinder and the Elite 550 Multiflex full servo multiple substrate inspection slitter rewinder.

The Elite Digiflex has been developed to convert and finish pre-printed digital, inkjet, or flexo media. This flexible system can print, apply additional coating, semi rotary or full rotary die cut, slit and rewind all in register in one, or multiple passes.

‘All our modular systems offer a high degree of flexibility which is why we are careful to discuss how they can be designed to meet every nuance of an operation’s requirements,’ stated Annemarie Rhodes, managing director. ‘That way we can offer a high return on investment. Why buy a solution that only meets today’s demands with no way of expanding as you do? Or why spend additional money on a machine that has more capabilities than you require? We want our customers to invest confidently in robust profit generating systems so we can help them build a more successful future.’

Features on the Elite Digiflex include a fast change over for maximum productivity and flexibility, the company’s own developed Automatic Print Positioning (APP) system for accurate plate registration and Automatic Die Registration (ADR) which reduces set up waste for a more cost-efficient re-register print and die cut production process. A digital servo drive also provides constant communication between all the servo axis.

The 300 mpm Elite 550 Multiflex is capable of slitting and rewinding a wide range of filmic substrates, including unsupported films and foils and flexible packaging substrates as fine as 11 microns. Fully servo driven, the multiple substrate inspection slitter rewinder incorporates a motion controller that maintains communication between all servo axis from the servo driven unwind through to the pacing roller and dual rewind system. The result is a performance with great accuracy of positioning and substrate tension control. Flexibility is offered with single or dual pneumatic lay-on rollers running as a single or dual web advance system with assured control on multiple films, foils and papers.