At Labelexpo in Brussels, Gallus showed how digital and conventional printing methods can be combined, with its ECS 340 press working alongside the Linoprint L digital printing system from Heidelberg.

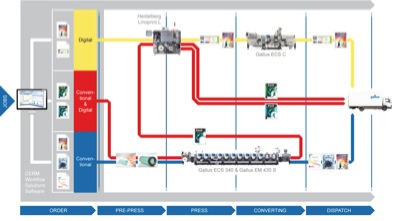

This workflow shows how the two technologies can be combined

This workflow shows how the two technologies can be combined

The Gallus Print Shop concept introduces a new way of producing labels. It combines the advantages of digital and conventional printing by networking the individual presses and controlling the production process centrally using the CERM MIS workflow software.

The software decides which printing process to use depending on the order made. This gives the option of a digitally printed label, a conventionally printed label or hybrid label using the two different methods. The machines involved, the Linoprint L and the ECS 340 can work together either inline or offline.

The company has been making changes to the ECS 340 and at Labelexpo said it had been developed to add major capabilities. The company said it can now offer less waste of materials and also has a quicker set up time. Energy efficiency is also a factor and one which it said was very important to the company.

The Gallus ECS 340

The Gallus ECS 340

Klaus Bachstein, CEO, said, ‘The range of inks is now better than 2009, investment in LED UV curing is still very high, but we have to help the early adapters in the industry to make the most of their investments. We hope to sell 300 ECS machines by the end of this year, which would be 300 in three years.’

A sample order with different surface finishes showed how the Print Shop concept works in a live demonstration, which lasted around 15 minutes. At the touch of a button, a label based on identical print data was printed simultaneously on the same standard substrate on all three machine systems in the Gallus Print Shop.

This makes the different printing technologies directly comparable. Samples are handed out during the demonstration for visitors to compare the print results achieved on the three different machine systems.