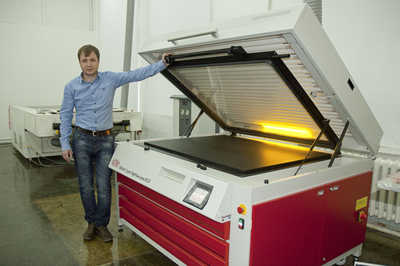

Pavel Belyaev, general director of Optimasmart with his new DuPont Cyrel DigiFlow 1000 ECLF

Optimasmart, a trade shop in Moscow, Russia, recently installed the new DuPont Cyrel DigiFlow 1000 ECLF exposure and light finisher.

‘We identified the flat top dot as a key industry trend early on,’ said Pavel Belyaev, general director. ‘We began researching the technology over a year ago, testing approaches and comparing performance: we even developed our own technology. Once we took all the relevant factors into consideration, including, quality, cost and productivity, it was clear that Cyrel DigiFlow demonstrated the optimum balance of properties for our business. Our basic workflow does not change and the new unit was installed within a day so we were quickly back up and running.’

Cyrel DigiFlow is a relatively simple and inexpensive modification to the existing line of exposure units. It adds a chamber that allows the creation of a controlled atmosphere during the main exposure allowing one-to-one reproduction of image elements on the plate.

This one-to-one reproduction is critical to optimising the effects of solid screening patterns. The Cyrel DigiFlow exposure units were designed for use on an ‘as needed’ basis, and can easily be switched off when the standard digital dot is the preferred result.

‘This is our fifth Cyrel DigiFlow installation in Russia to date, and the equipment continues to gain in popularity because it is easy to install and use with exceptional results,’ said Alexander Kosachev, technical sales representative, DuPont Packaging Graphics.

During the last three years, Optimasmart has established itself as a leader in platemaking capacity and technology. Cyrel Digiflow will enable the company to work with demanding wide flexible package orders and reach new customers, according to Alexander Oksuzyan, technical director. While new screening and platemaking technologies are simplifying the prepress process, he emphasised, prepress is still important.