If you have been following the ‘Looking back’ series celebrating Whitmar Publications 25th anniversary, then you may have noticed that today you are on a different website. That is because in 1994 FlexoTech magazine was launched, dedicated to flexography which was at the time the fastest growing printing process.

Initially distributed in the UK, the magazine would go on to circulate around the world. Just as its sister publication at the time, Paper Europe, it was devoted to bringing news and features from the industry to its readers.

The following extract is from the launch issue of FlexoTech, to see what was being said in Paper Europe at the time click here.

FlexoTech: November 1994

Developments in UV equipment technology

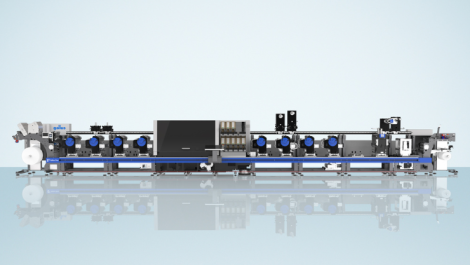

With the increase in press speeds, combined with more in-line colour combinations, the designers of UV systems are answering the demands by offering units with even greater lamp output than could have been envisaged ten years ago.

Whereas 80-100 W/cm were common lamp outputs in the early 1980’s today’s systems are frequently specified with 200 – 250 W/cm. To help increasing total power output, combinations of multi-lamp installation are used, as opposed to single lamp applications in the past.

The greater efficiency required from a UV system is best demonstrated in the narrow web and label converting industry. UV systems have to cope with several printing applications in line, i.e screen, letterpress and flexo. All apply differing film weights and curing requirements on a wide range of synthetic and heat sensitive film.

The easy solution is to apply the maximum curing energy as possible and hope that the ‘overkill’ will cope with every situation. Unfortunately many have found that this approach has been a costly one.

UV equipment manufacturers are constantly working to improve the efficiency and reliability of their systems.

GEW has designed into their controls a simple, user-friendly power control facility, giving the operator the option of manual or automatic power selection from the lamps. This gives savings on total power consumption, as well as reducing the risk of applying too much power, and heat.