As we entered the new millennium, FlexoTech was at the leading the industry speaking of the opportunities in combining digital and flexo, as we see in this extract.

FlexoTech: February 2000

Flexo Packaging demands

In recent times, the use of the flexographic process has become increasingly commonplace in more and more areas of packaging printing.

No other traditional print process can beat flexography for its ability to print onto such a diverse range of substrates. Besides packaging foil, self-adhesive labels or corrugated board, flexo printing is now extensively favoured in many markets.

Flexo printing of foils for packaging

This is an important market sector in which flexo has captured a dominant share. A continual shift of orders from packaging gravure printing to flexo is evident across Europe, especially with plastic foils and compounds. This trend may gather further momentum, as the latest press concepts such as digital drive technology become more readily available.

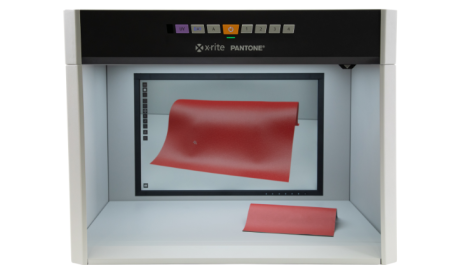

Flexible packaging materials and opportunities

As the trend in packaging continues towards shorter runs and high-end graphics on plastic films and corrugated, flexo is in an excellent position; flexo’s speed, its short set up time and the fact that flexo gobbles up less material than offset during set up, gives it a competitive edge.

Combination printing will open up opportunities in niche markets, one of which are cosmetics. As an anchor for the future, flexo combined with digital printing is one of several directions that many in the industry believe offers tremendous opportunity.