As we march through the ‘noughties’ FlexoTech was constantly giving readers the latest information on technology updates.

FlexoTech: July 2005

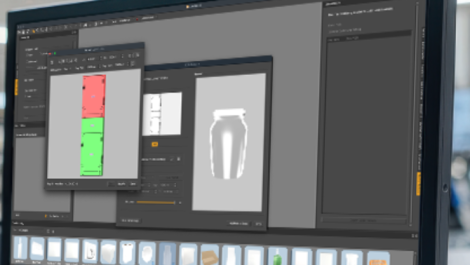

Development of direct engraving technology

Accelerated development of the Adless process technology for the production of seamless sleeves using liquid photopolymer has now set the stage for the betaphase trials. The initial trials are directed toward early implementation and market introduction of the fully commercial system. The Asahi Adless system will be the first presented to the public at the inauguration ceremony at Miller Graphics Limoges, France at the beginning of September.

Asahi Photoproducts provides plate making systems, comprising of liquid photopolymer APR and the AFT solid photopolymer plates together with advanced plate making equipment. These two systems are dedicated to meeting highly diversified market needs for flexography.

An area of special promise for the plate making and printing industry is that of seamless sleeve processes, because of their potential for reduced labour costs, higher productivity and printing quality. Seamless sleeve processes are currently of two basic types.

First the direct engraving type, in which the engraving is performed by CO2 lasers on seamless sleeves made of rubber and secondly the solvent type, which produces LAMS based seamless sleeves that are imagined by YAG or fibre laser, exposed and developed by solvent wash-out.