Roman Ostrzycki (left) and Jacek Mlynarczyk of Miller Graphics Poland with their certification

Miller Graphics Poland has become a Kodak certified partner after successfully meeting all requirements for the certification programme for Kodak’s Flexcel NX plates.

The programme is a relatively new initiative where achieving certified partner status demonstrates to printers and brand owners that Flexcel NX plates produced by certified providers are made to a standard global specification, representing a feature set that drives efficiency, stability and quality in print. It is a benchmark for quality and efficiency that reflects the high standards of the customer operations and the product being produced, and is supported by comprehensive data measurement and recommendations from satisfied clients.

‘We are delighted to receive this endorsement as it confirms the high quality of our plates, which is a priority for us,’ said Jacek Mlynarczyk, sales and marketing manager at Miller Graphics Poland.

Part of Miller Graphics group, the company is a flexo pre-press company with more than 20 years’ experience. It is now a leading edge operation that guarantees high quality and expert completion of even the most sophisticated jobs.

‘The Flexcel NX System, purchased in 2009, had a big role in our success,’ said Mr Mlynarczyk. ‘This investment positively influenced our production as it revolutionised the quality of our flexo printing. Therefore we were extremely happy to be the first company in Poland to adopt the technology. In our opinion, the system sets new standards in efficiency, stability and quality of flexo printing to positively influence our business as well.’

Since its inception, the company has specialised in developing a full pre-press process, from graphic design to a ready-to-press printing forme. It invested in many pioneering solutions early on and well-considered buys helped with the successful realisation of the most sophisticated jobs.

‘Kodak Flexcel NX System technology, as well as our long-term experience in handling jobs for flexo printing, enabled us to reach a quality level in flexo, previously unavailable on the Polish market until that time,’ added Roman Ostrzycki, production manager.

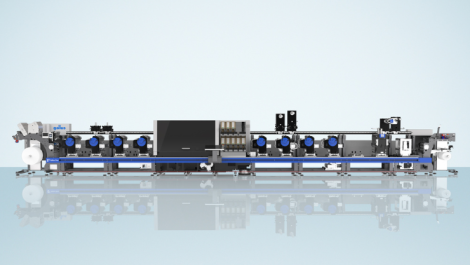

The system consists of a Flexcel NX imager, which offers process stability, outstanding imaging technology, semi-automatic operation, and easy maintenance. The Flexcel NX imager uses Squarespot imaging technology for process control to produce an image dot size as small as 10 microns on the Flexcel NX thermal imaging layer at a speed of 9.5 sqm per hour. After lamination to Flexcel NX plates for exposure, the result is a digital flexo plate imaging solution that provides exceptional printing results.

‘It guarantees the stability and predictability of the imaging process. As well as the stable dot structure, resulting in constantly high quality and repeatability of prints, it ensures excellent ink transfer and wide tonal gamut of images. Kodak’s technology expands developmental horizons for flexo printing and printing companies using plates produced in the system. It was one of the most important criteria when choosing the CTP solution. It opened up a perspective for us to reach a completely new group of customers who were previously using gravure printing,’ Mr Ostrzycki concluded.