Maca Srl has purchased an M5 Revo press to provide its customers with high quality in printing, quick set-up times and great flexibility in production and design.

‘Through the application of Revo Technology and Gidue Digital Automation we want to give our customers a new service that will provide high quality in printing, quick set-up times and great flexibility in production and design. The international market has quickly changed and nowadays Revo Technology can guarantee repeatability in quality and in delivery times with faster performances , like never before. Revo Technology and Gidue Digital Automation can really revolutionise the flexible packaging industry.’ said Salvatore Polverino, CEO.

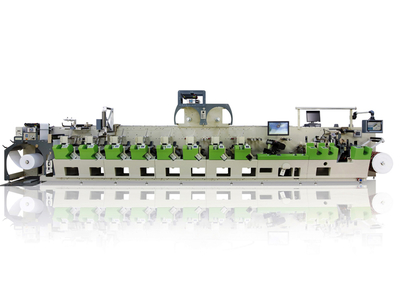

The M5 Revo press has a configuration of 630 mm width, nine printing units, Revo Technology for extended colour gamut and Gidue Digital Automation.

Revo is a team project with eight industry leaders cooperating to drive flexography towards the new ‘digital’ world of printing and converting. Process consistency, efficiency and cost reduction are the objectives of the Revo Digital Flexo Revolution, to win the labels and packaging challenge for short runs, global quality and total flexibility.

The technology uses UV Flexo Inks, Digital Automation from pre-press to printing process and extended colour gamut, which enables users to achieve repeatable and predictable PMS shades without changing the anilox or inks.

The most important benefits of the technology are the repeatability and predictability of the printing results, short set-up times and waste, total graphic flexibility to reproduce unlimited colours on the same job and fast change-overs that no need any manual intervention from the operator.