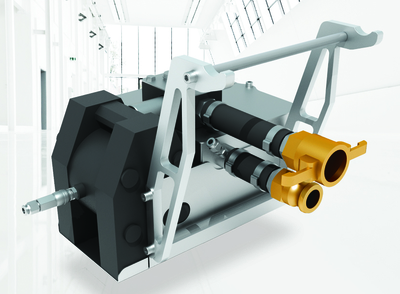

Soma Engineering has developed of a new ink cartridge system for spot colour printing on its 800 mm wide, Optima printing press.

The system offers printers a means of reducing ink costs on printing jobs where expensive spot colours, special effect and metallic formulations are required

These high pigment inks are expensive consumables and reducing ink volumes and residual waste permits printers to maintain profit margins while meeting end user price demands.

On a typical seven colour job using solvent based inks for example, the pumps are primed with CMYK and spot colours. The minimum volume of ink per colour in the system including doctor blade, ink hoses and ink bucket is 6 litres per colour, plus ink to print, for example, 400,000 labels.

When the print run is complete the 6 litres of ink per colour is returned to the ink bucket. This is feasible for the CMYK inks, but for Pantone spot colours and expensive metallic formulations that cover less than 1% of the print area, it is not practical. Using the ink cartridge system for the spot colours reduces ink waste and provides considerable savings. The ink cartridge system operates at a minimum level of one litre and at a maximum of three. Based on current experience Soma claims to have seen an average of 17.9% in ink savings.