OPM (Labels and Packaging Group) has halved production time for its studio and other departments after integrating Tharstern Primo MIS directly into an Esko Automation Engine.

Customers have welcomed the move to automation that brings the sales, customer and studio teams together on one workflow platform, which avoids a previous requirement to re-input data.

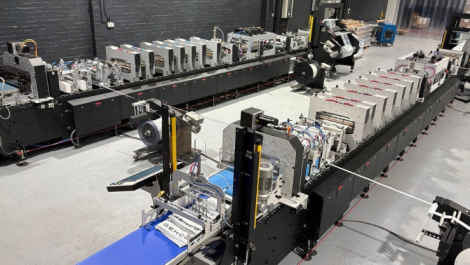

At the heart of the deal is the Primo software that effectively enables OPM to have complete work-time running in-time across products lines. These include print flexible packaging, sachets, films, laminates and self-adhesive labels within the food and beverage, pharmaceuticals, health, beauty, automotive and dietary markets.

OPM director Chris Ellison, who runs the business with his wife Sue, said, ‘As a brand custodian, we have to be in a position where we can manage the print and be in total control of what we are doing. Integrating the Esko Automation Engine with Tharstern has enabled us to overcome one of the bottlenecks that could be really challenging to a lean-efficient business.

‘The time it takes from getting initial artwork in through to an approved PDF has been halved. We are creating a complete workflow to run in time, which gives us the ability to scale our business accordingly. The Tharstern solution has been a revelation.’