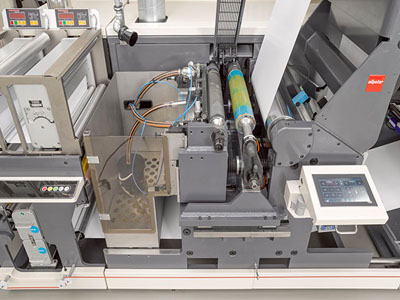

The Nilpeter FA-6* flexo press

The FA-6* mid-web flexo press for flexible packaging has been launched by Nilpeter to help printers tackle shorter run jobs with smaller repeat lengths.

The press has a maximum print width of 560 mm and a top mechanical speed of 175 m/min. Its sleeve system permits a very short web path with easy loading of tooling to reduce substrate wastage. The repeat length is 304.8 – 635 mm.

Inline functions include high speed solvent and water-based printing with reverse-side capability. UV-cured lamination capability includes glossy effects, surface protection, barrier solutions and cold foiling. There is also a solvent dry lamination option for special laminates, barriers, pouches and sachets.

Other options include the G-6 gravure unit. Using easy-load cassettes, it prints metallic inks, opaque white and special coatings, which increase the decorative options for flexible packaging. Reversible inkheads allow front or reverse-side printing. G-6 units have adjustable doctor blades, an ink circulation system, viscosity control and a drying and vacuum system for use with solvent-based products.

Fully customised configurations can include one or more of Nilpeter’s multi-purpose MP-6 converting units. Designed as ‘quick change’ platforms, they have automatic unwind and rewind capabilities. Film-based applications include wrap-around labels, tube laminates, pouches, sachets and shrink sleeves. MP-6 units offer multiple high intensity air drying and UV-curing of process works, inks, adhesives and coatings.

The FA-6* is configured with the CLEANINKING system for water-based or UV-cured flexo inks, and the PowerLink control system with individual job change functions.