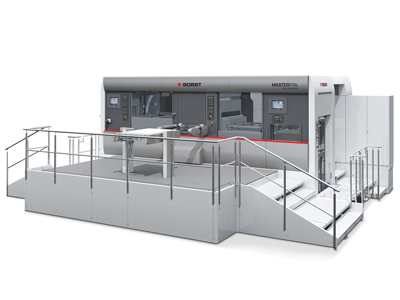

The Masterfoli 106 PR hot foil stamping press is just one of Bobst’s finishing launches

Bobst has launched the M6 UV flexo press at drupa, along with the CL 750D compact laminator, the MW CI flexo press range as well as new cutting, folding and foiling technology.

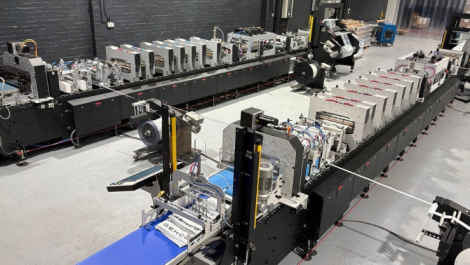

With specific configurations for folding carton and flexible packaging production, the M6 offers high productivity and low running costs. The press features nine-colour UV flexo printing and a 670 mm web width. For the folding carton industry a new converting section with automatic de-curler and a final sheeter with high pile delivery is being shown in-line with the Digital Flexo printing units. For the flexible packaging industry new non-stop unwinders and rewinders are available in-line with the Digital Flexo units.

Erik Bothorel, head of Bobst Business Unit Web-fed said, ‘Digital Flexo is one of the most innovative printing technologies in our industry. It delivers ‘digital’ flexibility in production and the lowest total cost of ownership. At drupa, BOBST has introduced specific features that make Digital Flexo perfect for the production of folding cartons and flexible packaging. It reinforces that we are leading innovation in technology designed for manufacturers in these industries.’

Also unveiled was the UV-Track technology for food packaging production, which confirms UV flexo technology as one of the safest printing processes. The UV technology records the curing of each meter of printed substrate, making UV flexo fully compliant with the strict safety requirements of food packaging supply.

Other flexo presses have also been launched by the company. The new MW CI flexo press range, is dedicated to minimising waste, and there is a new member of the Bobst Six range, 40SIX.

The two models of the new MW range, MW 85F & MW 125F, have been developed to help flexible packaging manufacturers efficiently produce short or long runs respectively. The 40SIX, available in several print widths, offers fully automated tool handling to speeds up.

Other launches include the CL 750D compact laminator, which allows converters to do ultra-short run laminating. Advances in sheet-fed die-cutting and folding & gluing processes are found in the new Mastercut 106 PER and Masterfold 110 A3 respectively, both of which offer higher running speeds, much faster make-readies, less waste, increased uptime, and technology that makes ‘zero-fault’ production achievable. These attributes also appear on the Masterfoli 106 PR hot foil stamping press on show, which features a new module, Foil Unwinder+, that is also making its drupa debut.

Jean-Pascal Bobst, CEO, said, ‘Bobst has always looked forward, identifying new trends and future needs, while simultaneously developing ways of carrying out existing processes more effectively. With our six world premieres, our many equipment enhancements and the extension of our portfolio of support services, we are continuing to show our innovation leadership in the packaging and labels sectors. This drupa our focus is on new, quality printing capabilities, featuring better flexo performance and the optimisation of the gravure process, along with digital flexo and digital printing solutions. As always, we will also reveal major enhancements to our range of converting equipment. Our presence here at drupa is more than just about innovation for today, it is also a way that we can show brand owners, packaging designers, carton makers and label manufacturers what the future could hold for them.’