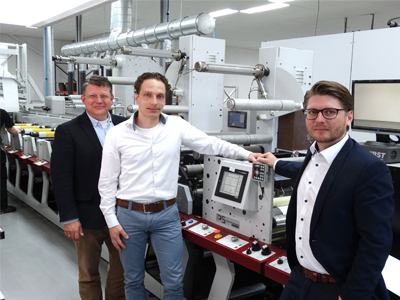

The EDNN team with the Mark Andy P5

Dutch label converter, Etikettendrukkerij-Noord Nederland (EDNN), has installed a Mark Andy P5 and consequently reduced turnaround times from weeks to days.

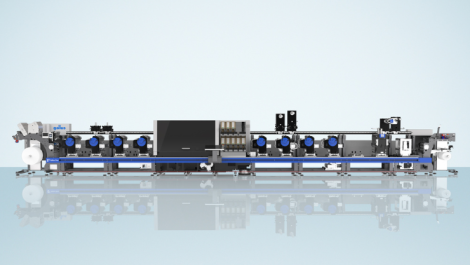

The P5, with its semi-servo control and its unsupported filmic substrates capabilities will build on the company’s product offering. The P5 has a 430 mm web width and is fitted with eight flexo print stations, corona treater, web cleaner, delam/relam, turn bars, two die cut stations and full UV curing.

EDNN has been a Mark Andy user since the company was founded in 2005 by Gert Talen, who installed a 254 mm eight colour 2200 and set to work with one employee. As the business grew, he added a second Mark Andy in 2008, this time a 430 mm 2200 model.

The watershed came in 2015 when Mr Talen sold a majority of the company shares to investors, and Vincent Belksma was recruited to run the business. Mr Belksma said, ‘We knew that extra capacity would offer our customers more security and relieve the pressure on our staff, but I also saw a need for restructuring to make production more efficient.

He continued, ‘In the end, we chose a Mark Andy Performance Series press because it was the most proven of all the competition and we knew we could rely on their after sales support, which as a small company is vital.’

With a growth in demand for ‘clear-on-clear’ or ‘no-label look’ using PE, and a desire to develop business in the eco packaging sector, Mr Belksma has set ambitious targets for the company moving forward. ‘I feel comfortable that the P5 will tackle anything we ask of it and allow us to grow our business into profitable new markets,’ he concluded. With a €3.5 million turnover the company continues to prosper with its original principles of customer service and value for money.