Device Manager bridges the gap between the pre-press department and the plate room

Reprographic and plate-making specialist VCG-Connect has improved its operational visibility and enabled a smoother workflow with the implementation of Esko’s Device Manager for flexo plate making.

An Esko customer for over 20 years, VGC-Connect was a beta site for the technology, which bridges the gap between the pre-press department and the plate room. ‘Device Manager is the result of a discussion about creating good visibility and interaction between pre-press and our devices,’ revealed David Piercy, operations director.

‘The instant visibility that Device Manager gives customers provides them with access to an up-to-the minute clear view of production,’ commented Robert Bruce, Esko Flexo product manager. ‘They can see if any action is required or how to better maximise their production. Fast turnaround jobs can easily be accommodated, allowing a more flexible approach to a demanding workload. Together, this functionality creates a much more efficient production environment.’

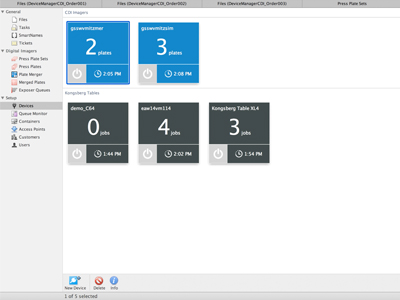

‘We have three Esko CDIs [Cyrel Digital Imagers] and a Kongsberg cutting table, and we can see what is happening on them at any time,’ explained Mr Piercy adds. ‘The software provides a real-time dashboard for production and creates an XML report that is fed back into our MIS. This helps our production planning process by enabling us to see what the production status is and to monitor our equipment utilisation. If there are potential bottlenecks or the need to handle a rush job, we can see what the best options are immediately. We can easily get a very clear overview that streamlines our operation significantly.

‘We can understand how the CDIs are being used and if we have the correct shift patterns to fully utilise our CDIs,’ he continued. ‘This helps us create a smoother workflow.

‘Production meetings are also smoother since the software shows what time the plates will be imaged,’ noted Mr Piercy. ‘We can then quickly understand if the job will be ready for the dispatching time.’

VGC-Connect also uses Esko Automation Engine to automatically execute pre-press functions in the background and, through integration with Device Manager, forward jobs directly to the platemaker. The company has further streamlined production with the addition of the Automated Flexo Platemaking Module to Automation Engine.