Folienprint employees in front of the new machines

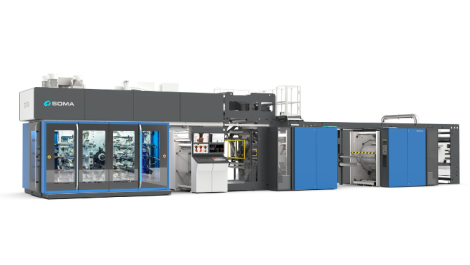

Gallin, Germany-based Folienprint has installed two Bobst 20SIX flexo presses to increase production capacity.

Part of the RAKO Group, Folienprint has begun operations in its new production hall after a construction period of almost a year to create extra space for two 20SIX central cylinder printing machines from Bobst.

The new 10-colour machines have a web width of 1100mm and a maximum repeat length of 800mm at a maximum production speed of 400m/min.

‘With the increase in our capacity, we are sending a signal that we are growing and can offer even more flexibility in our order handling,’ explained Doris Erhardt-Freitag, managing director of Folienprint.

Sustainability is an important company philosophy. ‘When we bought the new machines, it was vitally important to us that they were equipped with state-of-the-art technology for reducing waste and boosting energy efficiency,’ said Ms Erhardt-Freitag. The 20SIXs use the smartGPS graphics positioning system, developed by Bobst, to reduce the number of positioning and register errors. The presses are also fitted with a LEO (Low Energy Operation) system to cuts energy consumption during productive operation as well as when the machines are in standby.

Users of the new machinery have been impressed by the ease of operation and level of automation. ‘The new machines are faster to set up and require less manual operation,’ commented Karsten Meissner, print engineer at Folienprint.