The new nits from Phoseon are designed for narrow web presses

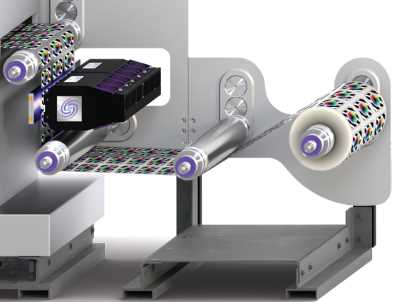

Phoseon has released two new products for UV-LED curing on narrow-web applications, the FirePower FP601 and FireJet FJ601.

The FirePower FP601 is a water-cooled solution with advanced control features using a Modbus interface and a high intensity output for the fastest possible cure speeds. The FireJet FJ601 simplifies retrofits with a self-contained air-cooled design that eliminates the need for air-extraction systems or water-cooling systems.

‘UV LED allows you to complete a wider range of print jobs with higher quality, faster and more consistently,’ said Jennifer Heathcote, regional sales manager at Phoseon Technology.

In addition to higher quality, UV LED curing for flexographic printing allows for better process control, less waste and the ability to run presses faster than with traditional narrow-web printing methods.

‘UV LED flexography uses raw chemistry that flows like a liquid. When the UV LED cures that liquid, it forms a long, continuous bond,’ said Sara Jennings, senior technical marketing engineer dedicated to flexographic and narrow web applications at Phoseon Technology. ‘What you apply to the surface is what you end up with; there is no deterioration, bleeding or fading.’

Creating a consistently sharp image is challenging on a porous material like paper, but it is compounded when printing on a nonporous surface like poly plastic. Traditional UV inks provide consistent colour, but due to the extreme heat of the arc lamps, it limits the types of materials that can be used.