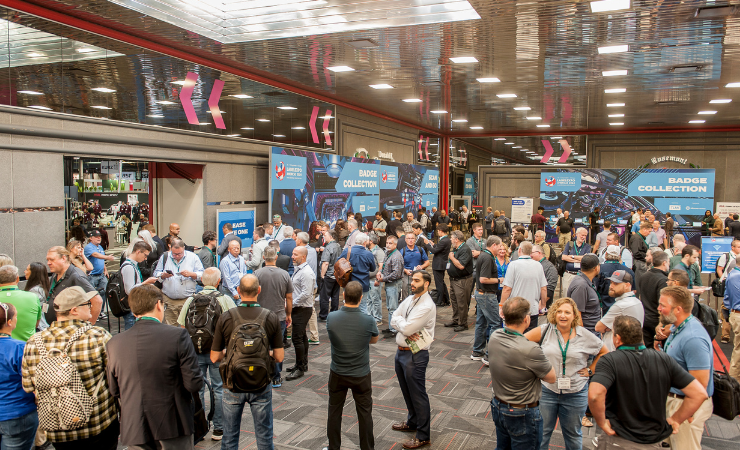

There were more than 12,000 attendees to Labelexpo Americas in September, with international attendance up by 33% on the previous edition. Andy Knaggs hopped across the Atlantic to join them.

Labelexpo Americas demonstrated that while digital printing continues to move forward, as might be expected, flexo printing is also progressing, which might be less so.

All of this was coming together on the Mark Andy booth, perhaps more than any other. Here could be found a new flexo press series – the Performance Series S9 – in 22-inch and 26-inch web widths, alongside the Digital Series HD HighSpeed 1200 inkjet/flexo hybrid press, capable of speeds of 146m/min at 1200 dpi resolution, and the Digital Pro MAX digital press, which Mark Andy says is the latest and most sophisticated version of its collaboration with Konica Minolta’s toner-based technology. The company was also breathing new life into its old 2200 series flexo press, pairing it with Domino’s iQ-R inkjet engine to create the DSiQ-R hybrid model.

FlexoTech was given a close-up look at the S9 flexo press. The ‘S’ in the title stands for Sleeve, and these are certainly lightweight and easy to change. The press is targeted at the flexible packaging sector, where Mark Andy says run lengths are declining and wide web production is ‘proving unprofitable’. It sees the S9 as a press that can take on shorter runs that are no longer viable on CI flexo presses.

Mark Andy company Rotoflex was also showing interesting technology, with a 700mm (28-inch) inspection rewinder, the VLI-700, for label converters going into packaging, and the VSI-330 with greater automation and data collection. Meanwhile, Mark Andy Print Products introduced a new portfolio of private-brand ‘Performance Line’ products, including anilox rollers, tooling, mounting, storage and handling equipment.

A new service offering launched at Labelexpo Americas was Mark Andy 360 Support, an end-to-end support program staffed with cross-functional experts to help customers maximise the use of their Mark Andy presses and finishing equipment.

Finding flexo

Nilpeter gave its FA-Line presses a US debut, although its plan to also show the new entry level FB-14 press, launched in June, was thwarted by logistics. On show was the latest version of Nilpeter’s FA-17, alongside the FA-26 press, which the company says is designed for short-run flexible packaging and labels. Visitors could also look at Nilpeter’s Digital Shadow virtual technology, enabling the use of data to improve on-press performance.

Italian manufacturer Lombardi Converting was present at the show, though without any press technology. Instead, it too was delving into the virtual realm, with a partnership with Siemens being demonstrated. The system shown helps to train operators, simulating best press set ups for the given job without the need for any waste incurred in trial and error.

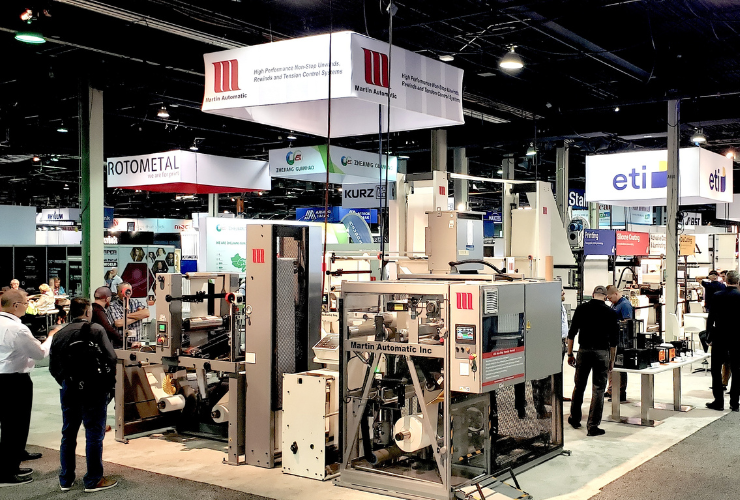

There was an intriguing collaboration on view in Chicago, with a labelstock converting line integrated across the exhibition booths of Martin Automatic, ETI and Lemu (plus Lundberg for waste removal), producing labelstock destined for use in a live job for a US printer called Channeled Resources.

According to Martin Automatic, the line performed ‘faultlessly’, and Gavin Rittmeyer, VP sales & marketing at the company, commented, ‘We have to understand the business model and requirements of the end users and be willing to help them get the best they can from the technology available. I believe we showed that to perfection at the Chicago show and demonstrated that it could be done without any risk to the end user. That’s what made it a unique display.’

Dialling up digital

There were some significant developments on the digital press side, with Dantex Group announcing a strategic partnership with Global Graphics to integrate the latter’s AI accelerated SmartDFE digital front end into the former’s Pico UV digital inkjet presses. The latest generation Pico was prominent on the Dantex stand, based on its PicoJet DRS technology, which features eight grey levels, rather than the standard four in digital inkjet, to provide ‘true’ 2400 dpi.

A ‘unique display’: the integrated labelstock converting line across the booths of Martin Automatic, ETI and Lemu

Gallus announced its MatteJet technology, which it says eliminates ‘inkjet gloss’ from prints. It is expected to be commercially available soon as an additional module to the Gallus One digital press. The firm’s CEO Dario Urbinati described it as a game changer, adding, ‘It’s the same ink and the same machine – just a modification of the surface of the inkjet droplet, leading to a modified result.’ Mr Urbinati revealed that some Gallus customers had seen MatteJet, adding, ‘The feedback is first astonishment, then excitement about what’s possible.’

Also in digital, there was an announcement that Esko and Canon are collaborating to integrate Esko’s software suite, including Automation Engine, with the under-development Canon LabelStream LS2000 inkjet press, which is scheduled to be available in the second half of 2025. The integration will enable a unified and automated workflow for label production, alongside ‘consistent, vibrant and precise’ colour reproduction.

Domino Printing Sciences launched a new mono inkjet printer at the trade fair – the K300 – which is intended as a flexible solution for converters to add variable data capabilities such as complex 2D codes, to analogue printing lines. And Konica Minolta highlighted its new web fed digital embellishment solution, the JETvarnish 3D Web 400, which integrates spot UV varnish, hot foil stamping and variable data printing in a single pass. It is tailored to the needs of the self-adhesive label and flexible packaging sectors, according to Konica Minolta.

Finishing lines

On the finishing side, both AB Graphic International (ABG) and Grafisk Maskinfabrik (GM) were exhibiting at the event. ABG had 12 machines on display, with several of them including new innovations to improve automation. The Vectra AutoSet is a new system for automatic feeding of cores. Several models of Digicon3 were shown, including with embellishment modules, and new flexo units for more speed and better print registration. And NSU Lite – an entry level model of ABG’s non-stop technology – was shown on its latest Converter platform, and on the Vectra ECTR Turret Rewinder.

GM, meanwhile, had four new systems to discuss with visitors to its booth, including a new high speed single anvil die cutter which was integrated with its DC350 finishing line to make the DC350Flex+. The machine has a die cutting speed of 120m/min in semi-rotary mode. There was also the HF350 Hot Foil & Embossing Machine, DVM350 Digital Varnish Module and DC350Mini compact finisher.

Maxcess was showing its 100% inspection technology VisionMax, used in wide web, which is now available for narrow web too, in four sizes up to 26-inches, as well as RotoRepel, a proprietary coating that allows for easier removal of adhesive materials from flexible or solid dies; and RotoScan, which automatically adjusts the die cutting anvil according to certain parameters. This is currently in beta testing and is due for release in 2025.

Actega introduced ACTKote UV Wash Off Primer, an APR-certified product that facilitates better recycling of shrink sleeves on PET bottles through enabling approved inks to wash cleanly off in caustic solution. Entirely unrelated to Actega, Beontag also launched a wash off label portfolio for PET bottles at the show.

There were also updates from Actega on its EcoLeaf and Signite technologies: Fujifilm and its 46k UV inkjet printbar were named as an integrated part of the EcoLeaf system, allowing printing at up to 80m/min; and it was revealed that the first fruits of Actega’s partnership with Makro Labelling, to develop and supply applicators and labelling modules for Signite, will launch in November this year.

New software came from eProductivity Software (ePS), which showed its Paxis ERP, ‘natively’ fit for smaller label converters. Paxis has been built ‘from the ground up’ for this market, according to ePS, and contains a range of tools specifically for managing digital and analogue label workflows, from estimating to item-based management and integrated production capabilities.