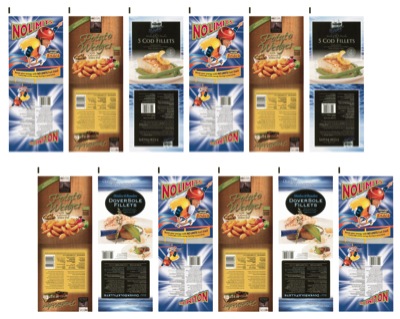

Flexible packaging produced with Kodak Flexcel NX plates

The photopolymer plate is not a static entity, but continues to evolve with new and improved products available from the manufacturers. With thermal, solvent and waterwash plates all still in the mix, we take a look at some of the solutions on the market.

It was with the introduction of the photopolymer plate in the early 1970s that flexographic printing took the first vital step on the path to becoming the sophisticated process itis today. Along the way, major technological breakthroughs have taken place and manufacturers still continue to improve on their existing products and develop new ones.

Tackling the issues

Kodak developed the Flexcel NX plate to combat the view that inconsistency, poor repeatability and compromised print quality are ‘just normal’ for flexo. Emma Schlotthauer, the company’s marketing manager for packaging solutions worldwide, said, ‘Printers are looking for consistent, predictable print with vibrant colours, high contrast and clean print with photorealistic reproduction.

They need profitable short runs, ideally by reducing set up times and combining designs across a web. Nowhere is this more evident than in the wide web flexible segment.’ The company’s mission statement for packaging is ‘Do More with Less’.

The Flexcel NX plates combined withDigicap NX screening offers significant impact on business with a step change in visual appearance that clients will recognise as gravure-like quality, while production efficiencies on press drive cost savings, and capabilities will change the way the packaging printer prints today.

The system consists of a thermal imaging layer which is processed separately and then laminated onto the plate, eliminating oxygen between the layers completely and in the process creating flat top dots.

Kodak’s SquareSpot imaging technology can produce dots as small as 10 microns and enables 1:1 reproduction of the dots on the plate. The DigiCap NX screening is a software solution that applies a micro level surface texturisation pattern to all the imaged elements of the plate.

This raises the ink transfer efficiency resulting in increases in achievable printed density, typically 0.4 in CMK, and with no increase in ink usage. Ms Schlotthauer said, ‘These new capabilities will allow the flexo industry to respond to the critical demand from brand owners for shorter and shorter runs with increased potential for versioning.

It should not go unnoticed, of course, that in addition there are significant positive sustainability side benefits that come from moves in this direction. Reduced materials, energy and waste, and better use of installed capital equipment can help everyone achieve the sustainability goals that the industry faces.

‘It’s time for flexo to come of age, take on gravure quality head on and do it in a smart way that increases efficiency, sustainability and the bottom line. When making plate and pre-press choices, printers need to be to sure to check off all items on the shopping list, and most importantly put the technology to the test.’

Ink pinning

Flexible packaging is in focus for many plate suppliers and there have been massive efforts in pre-press during the last couple of years to significantly improve the quality of the products and achieve quality that can rival gravure.

Customer expectation is now for smooth vignettes running to zero without any hard printing edge. Asahi’s contribution to this market demand is known as ‘Pinning Top Dot’ technology, which is designed to improve printed dot stability on press. One solution to achieve press stability is manipulation of the photopolymer oxygen inhibition effect.

The technique affects the way the cross-linking of the photopolymer is finished before the oxygen molecules find the time to inhibit the curing process. These various platemaking techniques are using the same chemical principle.

The company has taken a different approach to improve printing quality and has adopted pinning science, which is making use of the plate surface tension. Plates with a high point of ink pinning show a good transfer of ink to the substrate.

The surface energy through the process from anilox to substrate must increase in sequence. Differences exist between the plate pinning point from ink system to ink system. The higher plate contact angle facilitates a reduction of printing pressure during the production run for all ink systems. Longer plate life time can be achieved. The reduction in printing pressure also helps with plate stability on press.

Practical customer production runs with pinning top dot technology have been shown to reduce the ink filling-in at the mid tone area over the printing run. Less plate cleaning intervals and press downtime is commonly reported for users of Asahi plates with this technology.

David Galton, director, said, ‘Pinning top dot is Asahi’s response to the demand from brand owners and retailers to achieve production without a quality shift from the start to finish of the print run. The pressure to improve print quality at the same time as engineering cost out of the production process is relentless.

New technical developments in anilox and ink work in harmony with pinning top dot technology and produce packaging printing with lower ink film thickness giving more contrast and better definition to the printed feature on the substrate.’ The company is planning further material developments for this technology, designed to further push boundaries.

Developments in the product rather than the system will support a fast integration into existing production lines without the need of additional customer investments. Mr Galton concluded, ‘The quality increase within the flexo industry as a whole has enabled brands and retailers to make the conversion from alternative technologies to flexo possible. Printers can achieve higher print quality with more consistency throughout the print run by using pinning top dot technology, without having to change equipment, thereby adding value without any additional cost or investment.’

Spanning the globe

Since its market launch at the end of 2011, nyloflex NExT flat top dots technology has established itself globally, reports Flint Group. Offering a range of advantages to the user, especially for flexible packaging, printing plates exposed with this technology enable excellent ink transfer, particularly in solids.

In corrugated printing, a considerable reduction in fluting can be observed. The exposure technology is applicable for all digital flexo printing plates, regardless of plate thickness and format, and can be easily implemented into the existing digital workflow with no need for additional consumables.

As a modern full service partner for the packaging industry, Scholler Packaging invested in the technology at the end of last year after a series of tests.

Founded more than 40 years ago in Nuremberg, in Germany, the company has been part of Matthews since 2002. Not only a partner with regional and local printing houses and brand owners, it also acts as a global service provider in the areas of artwork, reproduction and data management, and supplies printing plates to printing houses across Europe.

The cooperation between Scholler and Flint Group started about 25 years ago. Since 2003, the working relationship and the product portfolio have been continually expanded and developed very positively, including a quarterly plates and production audit for external quality control.

‘In recent years, topics like HD, oxygen effect, flat top dots and micro structures, etc, have been very intensively discussed in the market,’ said Ludwig Haas, technical director at Scholler. ‘In the meantime, it’s a fact that with the available technologies, the so-called ‘oxygen effect’ shows several improvements to the printing process and thereby to the printing results too. However, one precondition for this is the appropriate adjustment in each press room.’

The decision to invest into a nyloflex NExT exposure system has proven to be the right choice for the packaging company. ‘The unit has been very well integrated into our workflow; it operates perfectly. The exposure with LED bars allows a constant UV output, thus facilitatingthe reproduction of finest details. In particular beneficial is the cooled exposure bed, which enables a fast UVA exposure and as a consequence a superb plate quality in terms of dimension, stability and floor,’ concluded Mr Haas.

Ludwig Haas, technical director at Scholler, checks the quality of a Flint nyloflex NExT plate

Ludwig Haas, technical director at Scholler, checks the quality of a Flint nyloflex NExT plate

Fast and friendly

The Aquaflex plate from Dantex offers fast production using very low energy and is an environmentally sustainable solution as the plate is processed in water. The processing system has a sophisticated filtration system, which can also run on filtered rainwater and the plate is compatible with all ink types. Colour strength and smooth pin hole free solids can be an issue that stops flexo winning more business from other processes.

The Aquaflex plate is achieving densities that are comparable with or without the addition of modification to assist solids to print stronger. Andy Beesley, business development director, said, ‘Traditionally produced solvent plates can leave the images looking weak and insipid in appearance, and suffer from heavy dot gain on highlights; however Aquaflex is achieving 1% minimum dots printing as low as 3% to 5% in flexibles and labels so far.’ Due to its ink release characteristics, the plate also goes a long way to tackle the common problem of dirtying in the mid-tones during printing. Furthermore, it requires very little cleaning during the longest print run.

Mr Beesley explained, ‘In the past durability of waterwash plates and alternative technologies to solvent plates have been questioned, but development over the last two years by Dantex dispels this theory and very long repeatable run lengths are now being achieved with Aquaflex in both flexibles and labels. Gear marking and barring on older presses can also be reduced.’ Dantex reports that a number of European label and flexible packaging print companies are successfully printing production jobs day in day out with outstanding results using Aquaflex plates.

Customer Richard Higgs, Ticket Media, UK, said, ‘With our old solvent- based processor coming to the end of its life, the Dantex Aquaflex system gave us an excellent opportunity to move away from the unpleasant working environment associated with solvent-based platemaking.

‘The ability of this plate system to hold a sharper dot than we had ever managed with our previous system has taken our print quality to the next level. This, along with a far quicker processing time, made the move to this system an easy decision to make.’ Andy Dodd, of flexible packaging specialists

RR Flexo Ltd UK, commented, ‘Since installing a Dantex AQF 900 inline processor, RR Flexo can now complete a week’s plate production in two to three working days if the need arises. We have seen an increase in colour strength since the introduction of the system, and dot gain has also dramatically reduced on the highlight dots.

Furthermore, we don’t experience many stoppages for plate cleaning, which is an added benefit that aids productivity.’ Mr Beesley concluded, ‘Whilst offering printers and repro houses a high quality and very productive system, the elimination of solvents and high speed processing is going to have an immediate and long term impact as a high quality, cleaner and greener solution for the flexographic printing industry.’

Covering the continents

The LUX flat top dot system from MacDermid was introduced three years ago and has seen considerable success with over 150 installations on six continents.

Latin America has been a leader in the adoption of flat top dots, with more than 50 installations in the region. One user, Excelencia, reports that it has seen vast quality improvements in both its flexible packaging and corrugated segments by taking advantage of the expanded colour gamut that the system enables.

‘We have been able to produce a much wider colour gamut with the LUX plates,’ said Fernando Garcia Herrera, director general. ‘The wider gamut is due to the fact that we are able to expose a 0.4% dot and hold it, reproducing it 1:1. Using this process, we are able to cover the tonal range that is lost with the typical digital process; all these dots are held on the plate using the LUX process.’

In Europe, printers and trade shops with a strong focus on quality, such SGS, Schawk, Chespa, Bulent Klise, Netsel and others, have also adopted the technology. One such company is VCG Connect, the UK-based repro house that supplies imaged plates to flexo printers throughout Europe.

While VCGinitially sought out a flat top dot solution because of the quality improvements that could be achieved, it ultimately chose the technology because of the flexibility it offered, making the decision to install the process in its facility in early 2011. ‘We were drawn to LUX because it presented a flexible solution: it was available in large format, and the investment needed was less than other alternatives that could get us the quality that we and our clients were looking for,’ commented managing director, Jim McCormack.

As a result, VCG reports a strong growth in business, providing the company the opportunity to compete against the quality offerings of gravure and offset. Mr McCormack said, ‘This technology is an enabler. It is enabling visionary flexo houses to tackle jobs that they could not before.’

Exopack, a converter of packaging and film materials headquartered in South Carolina, USA, added the platemaking process to its workflow in early 2011. One of the biggest benefits the company has experienced has been the ability to print consistently throughout a press run.

‘We’ve looked at it from roll to roll to roll, and LUX flat top is more consistent than what we’ve seen in the past. We’re able to get consistent print and consistent laydown without stopping the press,’ noted Jonas Scruggs, pre-press technical representative.

‘The system has helped us with a lot of the print quality programmes that we participate in.’ Each of these printers and reproduction houses are officially LUX certified by MacDermid Printing Solutions, meaning they have met the rigorous platemaking and printing standards established for certification.

Surface engineering

The order to address the issue of achieving higher solid ink density in flexible packaging print, DuPont’s has launched the new Performance Series of digital plate technologies in the Cyrel range, the DSP, Fast DFP and Fast DFR. While still maintaining high resolution, low dot gain and excellent run length, the plates have been developed with a specially engineered surface and can be incorporated in a standard digital workflow.

The company said that the new plates will enable flexible packaging printer to achieve quality that is indistinguishable from gravure printing and also improve sustainability. Productivity benefits include improved press uptime, reduced waste at start up, solids and screens on the same plate, reduced ink consumption and the ability to shift to extended colour gamut.