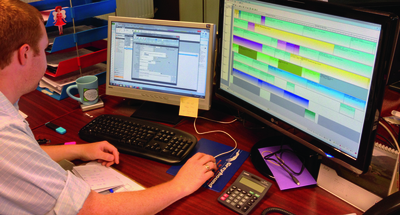

Shuttleworth offers an MIS that can be configured to the individual user’s needs

As print production becomes ever more automated and ‘hands-off,’ so this needs to be reflected in the administration side, preparing estimates, setting up job orders, tracking work, generating invoices and despatch notes, while keeping customers informed. All these functions can be handled with increasing automation and sophistication by today’s management information systems. By Simon Eccles.

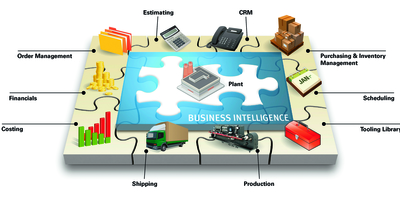

Broadly the requirements for labels and packaging are the same as for any printing sector management information system (MIS) – a core set of estimating and quotation functions plus job costing information gathering and analysis, with either built-in invoicing and accounts features or links to third party systems. There will be a way of tracking consumables inventory and usage, particularly substrates and ink, sometimes with ordering facilities that link directly to the supplier’s online ordering systems.

Scheduling and costs are aided by live information from shop floor data collection. Increasingly there are built-in customer relationship management modules, or links to third party CRMs (customer relationship management systems) that use the live tracking data.

Customer-accessible online services are also important. Willi Welsch, managing director of Quick Brown Fox, developer of the Aramis MIS for trade services, said, ‘In the past couple of years, there has been growing business for us in online job tracking,RFQ (request for quotation), sending orders and online approvals.’

Unique requirements

Functions specific to labels or packaging tend to be found in the estimating and costing modules, and the raw materials and cutting die ordering side.

According to Dawn Galley, technical pre-sales consultant at Tharstern, ‘The key for flexibles and labels is the questions users are asked as they are putting the estimate together, so the correct terminology and the correct fields are available for the information that needs to be entered. It is a work type specific for that sector.’

Clay Horsley, product manager at EFI Radius, said, ‘While overall the workflows of packaging products are fairly simple in comparison to commercial workflow, it is the various market segments (such as labels, cartons or flexibles) that determine the workflows and data requirements, each are very different.’

For example, he said, ‘Label type work, traditional analogue type flexo production, is all driven off the tooling (die) parameters. The tool controls the length and width, the gaps, the margins, and that feeds into how the product will be delivered to a customer.

Do they want to receive rolls of finished product, and if so, how many labels per roll? Or do they want a specific diameter of roll delivered regardless of the number of products? Or do they want to receive sheets of labels, and if so, how many down a sheet and across a sheet?’

Other factors that need to be handled by label estimation modules are the requirement for lamination and the growing use of extended content labels (such as fold-out instructions on pharmaceutical, industrial and other labels). ‘The logic required to print the extended content and apply it to the label production is an additional layer that must be addressed,’ said Mr Horsley.

Jonathan Richards, chairman of long-established MIS developer Imprint Business Systems, mentioned that there is often a need to mix print processes within the same run, citing hybrid screen and flexo presses, digital units on flexo label lines such as the FFEI-Nilpeter Caslon system, or a combination of processes used for different plies in flexible packages.

‘Flexible packaging also has its own unique requirements, from the various films that are utilised to the various units in which products are ordered and shipped,’ pointed out Mr Horsley. ‘While some flexibles customers are ordering X pieces, most are ordering by the MSF (thousand square feet) or by weight, or by rolls, etc. A packaging specific MIS system will need to be able to handle the conversion of these order/shipping/ invoicing units of measure to fully optimise production.’

Factoring in digital

As digital presses are starting to make an impact in label production (less so in packaging), they also need to be supported by the MIS. There are obvious practical differences in the workflows and costing, for instance there are reduced pre-press costs and times as no plates are used, while there is a much more restricted set of colours and processes compared to flexo or offset processes.

‘We are now moving into very short run digital label production so the ability to enter enough data to create an accurate cost/price and the production requirements with as little input and touch points as possible is growing each day,’ said Mr Horsley at EFI.

Katy Nightingale, UK business development manager at Label Traxx, agreed, ‘The nature of digital is a higher volume of lower value jobs,’ she pointed out. ‘However the estimating, generation of delivery notes and so on costs the same for a £500 order as a £5,000 one. It is ever more important to be very standardised for digital work. A lot of companies that move to digital find that it is important to get the admin stage side correct before anything else.’

Geoff Stephens, managing director of Time Harvest, said that there are some specific requirements for digital label presses. ‘It is quite a specialist business, especially in the costing. For instance, you have to take account of the frame size of the early HP Indigos in particular, as some larger labels don’t fit efficiently.’ The web-fed HP Indigo presses, unlike inkjets or Xeikons, have a fixed cut-off length.

EFI Radius ERP software is aimed at packaging compnaies

EFI Radius ERP software is aimed at packaging compnaies

Laser die-cutting is so far rarer than digital presses, but again introduces new factors at the estimating stage. Inkjets and the Xeikon toner presses have in effect infinite variability of repeat/cut-off lengths for labels, which introduces new options at the estimating and planning stages.

Xeikon, with its relatively wide 330 and 516 mm presses, has a new and so far unique ability to run multiple different label jobs simultaneously, using its VariLane software. Not only can the labels be different widths, but they can be different lengths with different quantities, so they may well finish at different times. This might present interesting challenges at the estimating stage.

On offer

Only a handful of MIS developers have produced systems that are specifically, or only, intended for labels or flexible packaging. A rather larger number offer modules or customisable features that work within their general purpose printing MIS to handle the specific requirements of more specialist print sectors.

Radius Solutions started as a UK developer of MIS specifically for flexible and folding packaging and labels. It was taken over by EFI in 2010 and renamed EFI Radius, since when it has continued to develop its systems from its Dronfield offices.

‘The EFI Radius ERP (enterprise resource planning) solution can handle the specifics needed for label production,’ said product manager, Clay Horsley, adding that there are also facilities for flexible packaging. ‘We are moving into quite a few companies that make their own films via extrusion processes,’ he said. ‘This opens up a whole new world of defining the ‘recipe’ of resins to produce a product, the amounts required to produce various gauges of films, colours of film, etc. And the ability to define the extruder itself and how many hoppers it contains and the products it can produces are critical.’

Flexible packaging

Imprint Business Systems was one of the first UK computer estimating system developers, founded some 35 years ago. The modular approach allows the company to offer dedicated solutions for a range of print sectors, including labels and, more unusually, flexible cartons.

The label configuration offers dedicated estimating and order creation, with control of production processes through schedule and work job management.

There is support for flat sheet and roll labels, with facilities for complex guillotining and ram punching, multi pass printing, varnishing and pattern gluing. For roll work, there are automatic calculations for cylinder size and cutter combinations against label gap range. Waste and unused roll materials are recorded, and unused roll lengths are used in estimates for future jobs.

‘We can also now support flexible packaging,’ said managing director, Jonathan Richards. ‘This was originally developed for a particular customer and is now on general release. It can handle the complex multiple plies used in many flexible packs, including mixtures of processes such as screen, flexo and gravure. This is a vastly different requirement to labels, as the films and the properties are different.’

The flexible packaging configuration includes estimating with quantities based on metres, items or kilograms required, with options for reel-to-reel, laminated pouches, bags on rolls, etc. Reel width, cylinder, laminate and re-wind calculations are also included.

Easily adaptable

The Optimus 2020 general purpose MIS was joined three years ago by Dash, a highly configurable and scalable modular MIS developed to meet the changing patterns of print buyers who think in terms of campaigns rather than ‘ink on paper’.

Backing this are modules, such as the sales enquiry and quote manager, campaign manager, sales generator (sales and profit analysis) and customer services (CRM). There is also a lot of emphasis on live information, including the Optimus Vision module that correlates and shows key performance indicators.

‘Dash was originally pitched for digital work but can really be adapted for anything, including labels and packaging,’ said managing director, Nicola Bisset. ‘A packaging printer in Australia is just ordering Dash to handle all sorts of carton and flexible work,’ she added. There are no full time label printers using Dash yet, but Ms Bisset is confident that it can be configured to handle their needs, including multi-part work.

Go configure

Based in Kettering, Shuttleworth Business Systems took over the label MIS developer Compass in 2004 and previously acquired Jenem, a packaging MIS developer, in 2002. These legacy systems have since been replaced by Shuttleworth’s own modular system.

‘Our applications are very user configurable, so you can tailor them to suit your requirements, whether that is in a flexographic environment, or for box making or sheet-fed,’ said joint managing director, Paul Deane. ‘The areas we are working at the moment are not specific to flexo, but the whole area of CRM, which is important for a modern manufacturing environment. We have done a lot of work in the past 18 months to two years on automating more traditional processes so people can handle their short run work far quicker than with traditional methods.’

Labels on track

Tailored Solutions Label Traxx is a dedicated label and packaging MIS intended in particular for narrow web flexo and digital label presses. Tailored Solutions was set up 20 years ago by Ken Meinhardt and David Porter: Mr Meinhardt had been production manager at a label company.

Modules include estimating, order processing, job costing, accounts receivable and payable, general ledger, quality control, stock products, and there are direct links to label stock ordering systems, including Avery Dennison, Fasson and UPM Raflatac. The Traxx Link allows printers selling stock items to link to stock warehouses.

eTraxx allows secure online customer links for quotation requests and order placement, while eTraxx Digital extends the options to live quotes of standardised jobs types, with stock and tool availability and artwork uploading.

Recent years have seen increasing support for digital label printing, including last year’s announcement of the Digi Traxx module that can automate order management for HP Indigo presses and send JDF production instructions either directly to the press or via an Esko Automation Engine production front end.

Estimating module

Tharsten attended Labelexpo for the first time in September. ‘We went to Labelexpo to show our wares as it is an area that we are very much geared towards now, together with the packaging sector, flexo included,’ said director Abdul Kassas. ‘Actually we have customers who have been using our labels and flexo packaging solutions for up to 15 years,’ added technical pre-sales consultant, Dawn Galley.

The label and packaging specifics are mainly within the estimating module, Ms Galley explained, ‘It is a method of estimating within the estimating module, and then the data would be tailored based on the type of print or product that the company is producing. We have full data files for the cutters and cylinders also, as that plays quite a significant part. The rest of the workflow would be the same for any print company, whether it is web, large format, sheetfed or digital.’

German fox

The Aramis solution from The Quick Brown Fox is primarily intended for pre-press and trade platemakers serving the flexible packaging, sleeve, labels and cartons sectors. It is less suited to printing companies, although managing director, Willi Welsch, said that some of his trade services users also have digital presses. QBF is based in Germany and has four current UK label users with two more just signed up.

Mr Welsch said that pre-press requirements for an MIS are much more complex than for printing and finishing, particularly because of the variables in how artwork is supplied and handled. As a pre-press MIS, it is particularly important to be able to communicate with pre-press production systems, he said, and emphasised Aramis’s bi-directional link to the Esko Automation Engine. It can be linked to Portos, QBF’s own customisable web portal for customers to create, approve, order and track jobs as well as link to other workflow systems, image asset databases, soft proofing systems and other admin systems. There is also a database of printing presses to help with sizes and layouts.

Xeikon’s Varilane software shown here is action at CS Labels

Xeikon’s Varilane software shown here is action at CS Labels

Harvesting time

Time Harvest was founded in 2003 to develop easy-to-use quoting and production management tools for digital printing companies. It is based on the popular FileMaker Pro database, which keeps costs down and allows it to run on Windows or Mac platforms. The estimating system in particular can be modified for the specific needs of label production. Managing director, Geoff Stephens, said there are users with HP Indigo, Xeikon and EFI Jetrion digital label presses.

Quotes are generated by the DigiQuote module and output as a PDF file that can be emailed to customers. In JobControl, successful quotes are converted to jobs by a single click. Batches of invoiced jobs can be exported as a .csv or Excel file for an external accounts system.

Expanded features

Data Design Services’ Accura software has been developed over a period of 20 years, offering a modular MIS for all aspects of print costing and estimating, CRM, administration and reporting. Managing director, Trevor Cock, said, ‘We have not so much modules but rather we have expanded our feature set over the years to support flexo and labels better.

For example, we added better material/substrate pricing options so that material can be priced per kilo, per square metre or linear metre, per CWT/tonne, etc.

‘Our press tables support both sheetfed and reelfed work. We have a die-cut form database built in which helps determine tooling costs and automate certain other estimate workflows like layout. We can also adjust for running speed of material, for example to allow for stretch.’