Operator installing an Apex GTT anilox roller

Paragon Print & Packaging demands consistency and standardisation. After extensive tests and analysis of its whole printing process, it decided to opt for GTT Genetic Transfer Technology anilox rollers from Apex Group of Companies.

Complete standardisation of the printing process is a key issue to Paragon Print & Packaging, the UK’s leading manufacturer of responsible packaging for the retail food industry.

As Europe’s largest label manufacturer, Paragon Labels produces more than 1.5 billion labels each month. With 52 flexographic label presses across six plants and a demand for extremely high printing quality, the company has a huge need for process control and stability; any waste must be avoided.

After analysing its printing processes, it was clear to the company that there was still some room for improvement and optimisation.

Therefore, it was decided to have a critical and in-depth look at all components used. The main goal as far as ink transfer was concerned, was to achieve customer specified digital colour targets, reduce spitting problems to zero, control the consistency of printing jobs and achieve outstanding results on HD Flexo. And so an 18-month journey began.

Extensive measurements with latest high-tech measuring systems showed that the devil was in the details and that understanding all variables and establishing controls was paramount to achieve total colour management. Once this fact became obvious, Paragon started testing and measuring Apex GTT rollers. After numerous tests on entry appraisal testing with Troika’s AniCAM measuring technology and press side tests using all the same inputs and detailed evaluation, it was clear that Apex GTT rollers gave the best performance by far with a variation of less than 1%.

The logical choice was therefore to implement GTT into the company’s printing processes, but knowing that GTT performs best when all printing components match perfectly, it was decided not only to standardise the anilox inventory but the whole printing process. Unlike many other co-suppliers, Paragon did not measure the ink off the press but directly on the press.

‘We know that the whole process does not work if the ink does not match,’ said Michael Marshall, operation manager at Paragon. ‘Issuing Ink Right First Time (RFT) to press is critical to delivery, quality and consistency, and Apex GTT technology has allowed us to control one of the critical inputs when achieving customer demands of a Delta E value less than 2.’

The consistency of the volume is checked using Troika’s AniCAM measuring system

The consistency of the volume is checked using Troika’s AniCAM measuring system

Measuring the best results when combining GTT with the inks of INX Ink finally lead Paragon to the decision to change not only the anilox rollers, but also the ink supplier.

Step-by-step the company changed the whole printing process and gained clear benefits: spitting problems with UV inks are now a thing of the past.

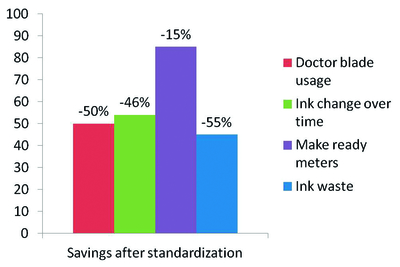

Significant cost savings on ink waste of 55%, doctor blade usage reduction of 50%, 46% reduction on ink change over time, and 15% reduction in makeready, show that Paragon took the right step at the right time.

As standardisation is a heavily discussed topic in the industry, it is interesting to see how it became possible at Paragon. ‘Understanding your process means being aware that there are points that might be small but nevertheless are of crucial importance. For us it became very clear that ink transfer is one of the key issues a printer needs to have control of in his job on a daily basis.

Cost savings achieved

Otherwise standardisation remains challenging, if not impossible,’ concluded Dennis Patterson, group operations director. ‘With Apex GTT, we selected a high-tech tool that gives us the highest degree of control around the ink transfer. At the same time we were able to reduce our anilox inventory thus saving a significant number of set up anilox roller changes across the business on a daily basis.’

Paragon has now achieved full control of its whole printing process on its more than 50 printing presses, which are manufactured by seven different OEMs, and all with a Delta E value of less than 2.

Through regular, precise and critical volume measurements of its GTT rollers, the company is able to maintain these high standards in quality and control.