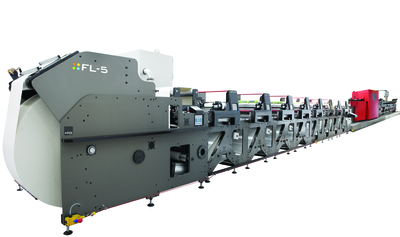

The FL-5 for cartons or flexible packaging

Press manufacturer Edale is expanding operations again by opening up a sales and support office in Thailand. It has also just introduced two new flexo presses as part of a refreshed and rebranded flexo press range, with another one due in 2014. Neel Madsen spoke to managing director, James Boughton.

Hampshire-based Edale seems to have its hand in many pies these days. At Labelexpo in Brussels, it not only had its own stand where an FL-3 flexo printing press was running continuously throughout the day, it also presented a finishing line in the HP hall in cooperation with AB Graphic International and had provided the transportation system for FFEI’s new Graphium modular digital UV inkjet press on show on the Fujifilm stand.

When we spoke to managing director James Boughton, he was keen to emphasise that the Edale we see today is a very different company to what it once was. He said, ‘Over the last 10 to 15 years, we have been working to redevelop the company and this has really accelerated in the past five years, which have seen a massive change for us. We are today OEM partners with some big businesses in the industry, and we want to get the message across that the Edale of old is long gone and that we have high quality technology kit.’

As part of its aim to simplify its offering, the new rebranded and expanded ‘Flexo Line’ now encompasses three presses with a fourth due to launch next year. The formerly known ‘Alpha’ compact press has become the FL-1 with typical applications being self-adhesive labels and tags working with substrates between 50 and 250 micron; the recently relaunched next generation FL-3 remains the same with typical applications being labels, tickets and filmic packaging (12-450 micron), while the Gamma is currently undergoing various design enhancements and can be configured to become either the FL-5 Carton or the FL-5 Flex Pack depending on the customer’s needs.

The FL-5 will have a high level of automation based on the technology used in the Digicon 3000 finishing line, which AB Graphics and Edale have developed in partnership. With a web width of 430 or 510 mm, the focus is on cartons and flexible packaging, and the first installation is going ahead early next year.

A wider version, the FL-7, is due to be launched next year. This is a mid web 760 mm wide press also for folding cartons and flexible packaging and also featuring the automation seen on the Digicon 3000, including semirotary die-cutting, auto die load and unload, auto slitting, 100% web inspection, auto register, electronic print and inking pressure system.

Louise Bailey, sales account manager, said, ‘We have grouped our range of flexographic printing presses into the ‘FL’ range, with the introduction of the FL-1 and FL-5 Carton and FL-5 Flex Pack to sit alongside the current FL-3. We believe this makes it easier for customers to understand the different levels and capabilities of each machine, at a quick glance. It also gives us a clear path to name the next machines as and when they are launched.’

Mr Boughton commented, ‘We are realistic in that we are never going to be manufacturing cheap presses. That is not our market. Our strategy is firmly built on innovation, technology and productivity, all British built engineering at its best, and we are leading the way in terms of adding automation and building significant OEM partnerships.’

Managing director, James Boughton

Managing director, James Boughton

A foot in digital

Edale has a long working relationship with Agfa Graphics going back some 12 years. In 2009, the two started developing the 760 mm platform,which is now being used for the Digicon 3000 and will also form the basis for the new FL-7. Edale’s proven web transportation technology has supported many inkjet printing solutions, for instance Agfa’s now discontinued :Dotrix single pass digital inkjet press, so the partnership with FFEI and Fujifilm, which is selling the Graphium press, is by no means new territory to the company.

But Labelexpo was not all about digital for the company. The Edale stand doubled up as a real production environment with the FL-3 flexo press being put through its paces running constantly all the day every day. ‘Being present on three stands at Labelexpo was very good for us,’ said Mr Boughton with a smile. ‘And while everyone else went for staged demos, we decided to do something a little bit different on our own stand and run the FL-3 press continuously throughout the day, in effect mimicking a real live production environment with all the challenges that this brings.

‘Visitors to our stand really seemed to appreciate that there was continuous action with the press either printing or in the process of being set up. We had a couple of minor hiccups, but that in fact only added to the experience and showed visitors that we could easily and quickly deal with the web breaking and other real life challenges.’

He continued, ‘I truly felt that at this Labelexpo, Edale stepped up to the plate and could hold its head high and was on a par with its bigger competitors. Our FL-3 press is comparable to others on the market. My plan was originally to spend most of my time in the HP hall with the Digicon, but in fact, I ended up mostly being on our own stand as we had a constant stream of visitors.’

Looking east

Continuing to expand and open up offices worldwide, the company has just announced its latest addition, namely Edale Asia Pacific, which will cover all regions of Asia Pacific, including Australia, Cambodia, Indonesia, Malaysia, Singapore, Thailand, Taiwan and Vietnam. A sales and support office based in Lamlukka, in Thailand, it is headed up by Tony Law as general manager and Pasin Sritong as sales manager.

The new office has already sold three Edale machines into the region. A five colour FL-1 compact flexo press for labels has gone to Bangkok, an eight colour FL-5 Carton line for the production of paper cups to Thailand, and most recently, a six colour FL-3 label and flexible packaging press to Malaysia.

The staff has already spent a great deal of time at the UK head office getting an in-depth feel for the product portfolio, participating in various agent training days and getting a week’s training during the factory acceptance for the FL-5 Carton line. This was followed by another week’s training during an FL-3 press installation in the UK in mid November.

‘We couldn’t be happier to be involved in the newly formed Edale Asia Pacific. Having worked with Edale for a number of years in a separate division, we are already impressed with the way that it does business as well as its range of machinery. Edale being a UK manufacturer means machine quality is guaranteed to be world class,’ said Mr Law.

‘We are pleased to have Edale Asia Pacific join our growing team of sales agents,’ said Mr Boughton. ‘Their key industry relationships and extensive knowledge of flexography, combined with the ability to service such a wide area make for a perfect fit for our growth strategies.’

Future outlook

We asked Mr Boughton to look into the crystal ball to see what the future holds for flexographic printing now that digital is becoming so pervasive in all areas of the labels and packaging market.

His answer was very optimistic. ‘The future of flexo is bright,’ he said. ‘With the new range of flexopresses, not just ours but generally, there is a definite pushback into what was once digital-only territory.

We can now happily print 1,000 metre jobs conventionally and with the innovation that has taken place in plate technology, the high print quality is there. Together this cancels out the benefits of digital. The majorityof work is still being printed conventionally and this is what people are relying on even if they have invested in digital.’