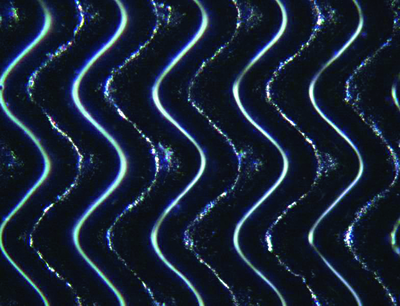

The GTT engraving with its open slalom channel

Despite its importance, consistency is not a word that usually rouses much excitement. However, when the benefits of consistent ink transfer are exploited, a whole range of possibilities is opened up to printers. This is what Apex offers with its GTT technology. By Michal Lodej.

Apex is promoting its GTT, Genetic Transfer Technology, products with far less pomp and ceremony than it used to. Previously described by the company as a revolution in the flexographic industry, it has learnt its lesson in trying to promise too much too soon. However what it can promise is consistency.

Bas van der Poel, technical sales manager, said, ‘GTT is not new but it has now become standardised. We can confidently state that GTT engravings are the most consistent and reproducible on the market today. We know this for a fact because it has undergone independent testing in some of the most exacting industrial conditions. A high precision, industry-specific tool determined that GTT rollers had tolerances of approximately 2.5% across the surface, and from engraving to engraving.’

The GTT slalom channel engraving pattern allows a better ink transfer to the plate as the ink is not trapped in individual cells, as with tradition anilox engravings. Instead the ink can flow freely through the channel.

This consistent ink transfer allows printers to calculate precisely how much ink will be on the plate, and so can accurately recreate Pantone colours on the press from using just the four process colours. The company claims that 80% of Pantone colours can be created with CMYK and that using seven colours can replicate up to 90% of Pantone colours dependent on the print parameters used.

It can also improve the quality of printing, which is more pronounced with the latest plate technology, however even without the most up to date plates, the company can assure that printing will be consistent.

If a customer is curious about the benefits of the technology, they can have a trial with the GTT metering roller, and will even be provided with newer technology plates from PPP Digital Imaging, so they can see for themselves what difference it makes. Apex works closely with repro specialist, such as PPP, that have experience with GTT technology, but Mr van der Poel says customers can go with their own repro company and it is always their own choice.

Making savings

High quality is important, however, the company’s solution is also appealing to its customers’ pockets. Saving money comes from the fact that all printing components stay in the machine as each printing station is dedicated to one of the process colours. If you are printing multiple tones from the same four colours there is no need to remove the anilox rollers, which is when damage is more likely to happen.

Removing the need to change colours in the printing stations also means there is less down time and less waste. The company is confident that this will help its customers save money on doctor blades and wash up times too, however when asked about the possibility of saving money on ink, Mr van der Poel said this is a more complex issue. ‘Yes it could save on ink but the trouble is I can’t give any figures on that because there are so many other factors which affect ink consumption, it is not solely up to the anilox roller.’

Nevertheless, GTT technology can make the printing process more efficient and environmentally friendly, and the accurate recreation of Pantone colours also means two designs can fit onto one plate.

The company offers a range of different roller types from XS to XL, think t-shirts, with the XS leading the way in high definition printing and the XL used for instance for printing a nice full tone white.

Apex’s headquarters in Hapert, the Netherlands

Despite coming off the back of an economic recession, the company is in good shape after it saw a rise in business over that period. Jeanine Graat, global marketing manager, said, ‘Interest in the GTT products has grown since 2008. As budgets were squeezed printers were looking at ways to save money, and so the benefits that came with using the GTT anilox rollers became attractive. Over the past 12 months, Apex achieved an average global sales growth of 30%, not only on GTT, but also on the conventional anilox rollers, which still form an important part of the total product range.’

Creating channels

At the company headquarters near Eindhoven, the Netherlands, all repairs and checks are all handled in house so the company can be certain the products will be completed to its high standards, maintaining the quality of the brand.

A modern, state-of-the-art, air-conditioned laser engraving department houses the latest technology lasers, some working on patented GTT technology, which has been further developed over the past three years, and others working on its range of conventional anilox rollers.

The anilox starts out as a steel roll, which forms the base, then the ceramic is built up over it. A ceramic and titanium mix is first ground down into powder, mixed with water and then sprayed onto the base. It is then fused to the base with a flame. Once the ceramic is built up it needs to be smoothed down. Smoothness is the most important aspect of any anilox roller, but when using a material as hard as ceramic there is only one substance, which is physically able to do this, diamond.

The GTT metering rollers are made by a laser-cutting slalom structured channels as opposed to the tradition hexagonal cells. This type of engraving is smoother as the laser is working as a constant beam rather than through quick short bursts that create the hexagonal cells. It can also create shallower cells, which again helps the ink transfer to the plate.

For the conventional anilox rollers, the laser still plays an important role. Apex uses a technology called UltraMelt, which can be described as controlling the intensity range of the laser beam that engraves the anilox cells. The engraving procedure of each cell starts with an extreme power shot that determines the main shape of the cell. During a secondary low-powered after treatment, the laser beam closes and hardens the ceramic surface making the surface smooth and shining like a mirror. The company can produce any cell pattern, from hexagonal to Channellox and from LongCell to Trihelical.

The cells and patterns will be checked against both the customer’s requirements and the company’s own high standards. After completion, the rollers are exported worldwide using with the company’s own logistics department.

Apex offers ceramic laser engraved and mechanically engraved chrome plated metering rollers

It is important that the headquarters’ stringent quality control is replicated throughout the company’s offices across the globe. Several times a year each satellite office will send an anilox roller to be tested by the Hapert development centre to ensure that the quality of brand is being maintained and that entity is calibrated in the same way.

Global player

Having grown over the last 15 years from a small business to a worldwide producer of ink metering rollers, the company has today over 5,000 customers and production locations in India, the USA, Brazil and Italy as well as its headquarters in Hapert, in the Netherlands. With a total of 220 employees, it has a sales force of more than 80 and six sales offices.

The company works closely with a number of partners and took part in the REVO open house event at Gidue’s headquarters in Florence in June, where the so-called ‘Digital Flexo Revolution’ was demonstrated.

Ms Graat commented, ‘Being active on a global scale offering customers the same level of quality all around the world is important to Apex, just as important as being innovative and leading. Apex recently won an award for the most innovative development in the field of laser engraving, handed by University of Twente, an important knowledge centre in Holland.’

All printers know how important consistency is, and if there is a way to improve it, most would agree it is important investment area. Apex has moved away from making claims that its technology is a revolution in the flexo industry, however only time will tell just how important GTT technology will be in the evolution of flexo.