The laser facility at Cheshire Anilox Technology

As the vehicle that meters out the amount of ink that ends up on the substrate, the anilox is central to the flexo printing process. There are various schools of thought as to which cell engraving enables the best ink release, some favours elongated hexagonal cells while others swear by open channel engraving patterns. With the huge choice on the market today, selecting the right anilox for the job is a challenge. By Neel Madsen.

Together with the photopolymer plate, the anilox truly defines flexo printing and manufacturers are spending a lot of time and money on developing these in order to be able to give their customers the best possible ink metering device. Research and development into cell shapes and ink release continues, and your supplier can guide you in your choice of anilox inventory to avoid costly mistakes.

Longer cells

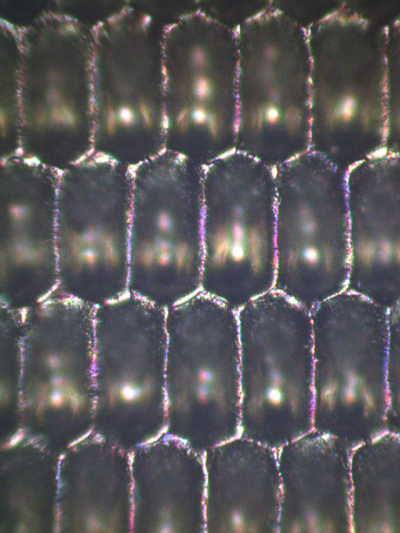

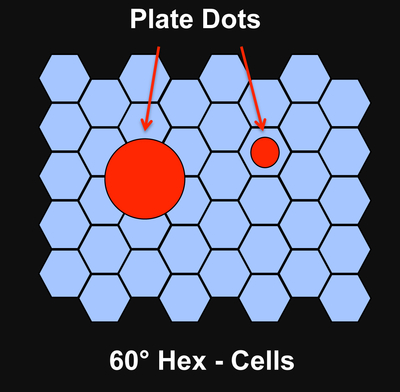

Time was when a standard anilox with 60° hexagonal cells was used for most jobs and it still offer consistent, reliable ink transfer with balanced support of the plate dots. However, as flexo printing develops so must the anilox.

Technical sales manager at Pamarco Global Graphics, David Parr, said, ‘Flexo is generally a forgiving print process, allowing printers to do things in a variety of ways, therefore having the wrong anilox in your press isn’t always immediately obvious. However, as the demands of the market mean that you have to print higher quality, print faster, change jobs more frequently, reduce your downtime and costs, just to remain competitive, it is vital for flexo printers to understand and control every part of the flexo process to suit the exact needs of their customers.’

Mr Parr explained that a common misconception concerning ink transfer from the anilox to the plate is that the cell will empty almost all its content, much like emptying a coffee cup, when in reality transfer rates are only between 25% and 50% depending on cell shape, ink viscosity and press speed. He said, ‘If you want to a large ink film for higher density and better coverage, you need to either have bigger cells, or have cell shapes that transfer a high amount of the ink. In contrast, if you have too much ink, causing defects like dot bridging and dirty print, you need to reduce ink film by reducing the size of the cells.’

This simple concept is, however, increasingly complicated by the fact that the demand for higher resolution printing means that flexo plate dots are getting smaller and smaller. For example, flexo plate screens of 150 l/in (59 l/cm) have a highlight dot diameter of 19 microns and using the general rule of matching the cell opening to the dot diameter would mean the selection of an anilox of 1120 l/in (440 l/cm). Finer anilox screens reduce the size of the cell opening, which generally means a proportionate decrease in cell depth and therefore a reduction in cell volume and less ink transfer. This problem cannot be solved by increasing the depth of the cell as this may lead to more ink remaining in the cell and faster ‘plugging’ of cells, loss of print density, all leading to downtime of the press and rejection of the print.

Pamarco’s solution to this problem has been the development of extended cell technology, the EFlo. The EFlo engraving has double length cells in the direction of printing which offer several advantages for flexo printing. First the elongated cells can carry and deliver to the printing plate a much larger amount of ink than conventional 60° hexagonal shaped cells. Secondly, the cells are engraved at a consistent angle of 75° to ensure no moiré clash with flexo plate screens. The increase in ink transfer to the printing plate means that screen counts can be increased without compromising on the depth to opening ratios, maintaining good support to flexo plate dots and providing excellent ink film thicknesses on to the printing plate. Finally, the open structure also keeps anilox cells cleaner for longer, helping to reduce downtime, loss of print density and quality.

‘Since EFlo’s introduction in 2010, extended anilox cell technology has been extensively proven in all flexo printing disciplines and is now widely adopted as an industry standard for a substantial number of high quality flexo printing applications. This includes both brown box and high graphic post-print corrugated and HD flexo, currently being used extensively in flexible film and paper printing,’ concluded Mr Parr.

Opening a new channel

One solution to the drive for reduced costs is fixed palette printing, using only CMYK (plus orange, green and violet) avoiding the need for Pantones. This requires complete stability of the printing process and that includes the anilox.

The EFlo elongated cell structure from Pamarco

Sonia Arcos, sales director at Cheshire Anilox Technology, said, ‘As print runs are getting shorter and shorter, and the costs are being driven down with reduced margins throughout the supply chain, the need for faster changeovers makes printing with 4 to 7 colour process a very appealing option. The benefits of using less plates, tape, ink and having less anilox wash ups and production downtime are obvious. However, in order to achieve the required colour densities and a comparable colour gamut, the anilox must provide a highly consistent and uniform volume of ink to the plate. Improving ink transfer efficiency from the anilox to the plate is key for the success of this technique.’

The investment in 2012 in a new 500 Watt multi-hit fibre laser with custom pulse, enabled Cheshire to develop a wide range of new engravings.

The latest innovation is MaxfloXT, a channel engraving with a continuous spiral structure, which is compatible with all ink types and available up to 2,000 lpi. The screening software in the new laser has allowed Cheshire to control the internal dimensions of the continuous spiral channel, widening it to provide a higher ink carrying capacity and improve its release characteristics.

Ms Arcos explained, ‘The concept of using channel engravings to improve ink transfer efficiency is not a new one. Channels have been used for many years as an effective means of increasing the ink flow within the anilox improving transfer efficiency. However, ink film thickness and uniformity was always more difficult to control in conventional channel engravings. The real challenge is to design a channel that can effectively control the volume of ink transferred as well as maximise ink evacuation from the anilox. MaxfloXT has accomplished both.’

This new engraving promises to improve ink transfer by up to 15%. Its continuous cell structure has 50% less land area than 60° conventional engravings as there are less cell walls, offering a more efficient and finer ink distribution. Customers are reporting an average increase in colour densities of up to 10% compared to conventional engravings, while the smoothness of coverage and a reduction of pinholing are other reported benefits of MaxfloXT.

Results are immediately visible in the print, increased densities provide higher image contrast and greater colour vibrancy. Increasing the density across the full tonal range broadens the available range of colours and expands the process colour gamut.

Another reported advantage of the new channel engraving is that when used with UV inks, it eradicates the common problem of ink ‘spitting’. The continuous engraving improves the inkflow within the anilox stopping the build up of ink behind the doctor blade which forces it to lift and cause the ink spray or spitting.

The company has also developed a new advanced sealant, which reduces porosity to less than 0.5% and furthermore offers an improved protection against corrosion. The vacuum infiltrated sealant penetrates extremely fine porosity and deposit a barrier film on the cell walls, lowering the coating surface energy. Its hydrophobic characteristics maximise the evacuation of ink from the cells and provide a stronger shield to the anilox metallic base. All Cheshire’s rollers are treated with this sealant.

More laser power

Sandon Global has installed its fifth thermal fibre optic laser, which has been supplied by Advanced Laser Engineering (ALE). The company said that this investment reflects its need to increase capacity and meet growing customer demand for its products. The system uses new materials and technologies in beam delivery optics that refine production and optimise manufacture. The technology enables consistency and subsequent quality of anilox engravings at higher screen counts.

Courtesy of Harper Corp

Courtesy of Harper Corp

‘We have been working in partnership with ALE on new concepts in laser technology to meet our high demands for some time,’ said managing director, John Millington. ‘The new laser will give us the ability to carry out some exciting new product developments. Sandon Global is determined to constantly evolve engraving concepts through ongoing experimentation. The fifth laser is crucial in driving these latest developments by utilising its technological advancements and also increasing our capacity so that we can dedicate increasing time to research and development. The new laser will be capable of producing greater latitudes of engravings aiming to increase line counts whilst maintaining greater volume capability than previously available.’

A sixth thermal fibre optic laser is also on order for commissioning in August 2014. Mr Millington concluded, ‘The new laser represents a major investment for the company and demonstrates our continued investment programme at a time when the global economy is in recovery. We are very confident in the future of the flexographic printing industry and will continue to support its success and progress.’

The company produces a comprehensive range of engravings, including the iPro for HD printing, which features an open cell design for increased release characteristics to avoid problems such as ink starvation at high printing speeds. Its high opacity white (HOW) and high opacity colour (HOC) were developed for the narrow web market, while for wide web printing, there is the high volume process (HVP) engraving.

Nano nano

Anilox Laser Technology Ltd (ALT) introduced its Nano technology in 2013.

Managing director, Anthony Jewell, explained, ‘We developed Nano to give the printers a new option for high ink transfer whilst under the strict constraints of the flexographic process. Since the development, we have converted a considerable amount of customers to Nano and they are seeing improved ink transfer whilst using high cell counts and reduced cell depth. This results in lower ink consumption and decreased cleaning cycles. Also the demand for high cell counts can sometimes see an increase in doctor blade scoring or marking to the anilox surface. This has been massively reduced in most applications with the introduction of Nano anilox technology.’

Sandon Global’s laser room

The company has also continued a planned investment programme during 2014 with the introduction of a new micro polishing system and additional microscope measurement equipment to further increase the capacity for the accurate production of anilox rollers and sleeves.

Mr Jewell said, ‘We have worked closely with some key customers to help them improve their Pantone colour matching processes and therefore reduce print set up times. This is achieved by the unique volumetric measurement process we adopt with every anilox produced.

‘With the introduction of HD flexo plate technology, it is even more important to control the cell geometry and ink volume release. All areas of the industry are developing products that complements each process, anilox included, and we feel that the flexography is becoming stronger and will be the preferred print process for the future.’

ALT is committed to further development and is currently working on other cell structures that will be available for test and evaluation later this year. There are also plans to purchase a third laser engraving system towards the end of 2014.

Consider the variables

When working with specifics print targets and high-end printing, you should know the size of the minimum dot and the opening of the anilox cells your supplier is recommending. Ideally it is best to have the cell opening equal to or less then the size of your minimum dot. This will ensure that you can achieve precise clean print, soft vignettes and no edges when fading to zero, explained Harper Corporation’s Alex James. Selecting the correct anilox, however, is not just a question of matching the size of the plate dot, there are many more variables to consider when deciding which engraving would be the most appropriate for your application.

‘Variables to consider can be numerous, so get started by documenting the obvious ones. Begin with your press type and production speed. The type of ink you plan on using will be another factor, as is substrate choices, especially when dealing with film vs paper and uncoated substrates. Uncoated substrates will naturally required more volume of ink due to the absorptive nature of the material. Along with those variables, your polymer choice and your plate technology will also play a major role, especially when using the different imaging technologies currently available. In hand with the different plate imaging technologies, there are also the different tape options that can be used in combination with your polymer.’

For the precise transfer of thin ink films with micron accuracy, Harper offers the XLT (Xtreme Laser Technology) engraving. The company invested over $5.3 million in the development and installation of the XLT, which has also paved the way for a new product, known as XVR, engineered for extended volume ranges and well suited for combination printing of solid and line work on one plate. For heavily pigmented inks and coatings, it has the XDW channel engraving.

‘Selecting the right anilox for your needs involves proper communication of your variables to your anilox supplier. Thankfully in today’s industry there are a variety of different engravings to choose from. Work with your co-suppliers and anilox supplier when embarking on new projects. Keep in mind your variables and your print target and with proper communication your anilox supplier will be able to find a solution for any of your print challenges,’ recommended Mr James.