Close-up of gap between magnetic cylinder and GapControl

Label stock materials, and in particular release liners, are becoming thinner, to save on costs and waste. This has serious implications for the die-cutting process. Neel Madsen spoke to a couple of manufacturers to hear how they are meeting this and other challenges.

With substrates and release liners getting ever thinner, die-cutting has become a precise science dealing with measurements that are less than a third of the diameter of a human hair. The cutting needs to be precise and in register in order to present a final high quality product.

Controlling the gap

Die-cutting is significantly more difficult on a 30 or 23 micron PET liner compared to a conventional 55 micron glassine liner, for example. This has to do with the nature of the process, which aims to cut the face material without damaging the liner. With hard face materials like paper or PP, the die aims to compress the material until it bursts. However, when die-cutting synthetic materials like PE, PVC or new MDO films, the cutting edge of the die-cutting tool needs to penetrate such materials until it touches the release liner. Moreover, PET release liners are not compressible and are therefore very sensitive to any inaccuracies in the die-cutting tool.

Wink’s SuperCut flexible dies are produced with a special blade geometry and minimum height tolerances of only ± 2 microns. As an option, the company offers the ProShift technology for staggered die-cutting. The staggering of labels in web direction reduces the length of the simultaneously cutting transversal lines, so that the cutting pressure can be considerably reduced. This is extremely beneficial for protecting the liner material, and increases overall efficiency.

A very accurate tool is still no guarantee for flawless die-cutting results, since the flexible die is only one part of the complex die-cutting process. The whole cutting unit with all its cylinders and other components needs to be in an absolutely flawless and clean condition. This means that all tolerances and true running accuracies need to be within ± 3 microns, and moreover no dirt or corrosion should counteract them.

Wink has introduced the MCR coating specifically for die-cutting abrasive materials

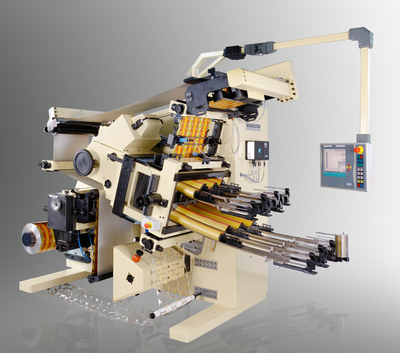

The wide range of materials and ever thinner liners make special demands on all die-cutting components. Adjustable anvil rollers can be very helpful in this context, as they permit a variable adaptation of the gap to the respective requirements. However, in some applications problems arise with conventional systems, in particular with cutting through larger working widths and high production speeds.

After long research and development work, Wink introduced the GapControl adjustable anvil roller, which overcomes these limitations. The operator can adapt the gap to specific needs easily and with great accuracy. The system is convincing with highly precise double-sided gap adjustment and its particularly stable construction which even makes cutting through (metal-to-metal) possible without any problems. The company is launching GapControl in North America at Labelexpo Americas, after a very successful introduction on the European market in 2013.

‘As well as the trend towards thinner labelstock materials, we are also seeing an increase of very demanding face materials and inks, which are very abrasive and thus impairing the die-cutting performance,’ said Dr Andre Gysbers, marketing director.

Wink also has a new ultra-hard MCR coating for flexible dies which promises to significantly increase the durability of the tooling, especially when die-cutting very abrasive (thermal) materials in long runs. In combination with laser hardening, the MCR coating should lead to a maximum service life.

Aspects of die-cutting

Over the last few years, Berhalter has introduced a number of innovations to the market. Its die-cutting systems are used for a number of applications, including flat packaging lids made from aluminium or polyester, such as Nestlé yoghurt lids, as well as for packaging lids with relief impressions, like Philadelphia lids for cheese spread. Deep-drawn aluminium lids used for pet food like Sheba or Cesar enhances the extensive range of product opportunities, but Berhalter die-cutting machines can also be used to produce paper labels, eg on beer bottles and labels for IML applications, such as those on Starbucks coffee cups.

The company said it is necessary to consider a number different aspects that can influence the die-cutting process and thereby the final product:

Material characteristics.Not all material specifications offer the same performance in terms of printability, die-cutting and application. For example, stretching may cause problems on both printing press and die-cutting machine. Consequently, it is very important to have an integrated fully automatic tension control system in combination with a as precise cutting tool as possible, enabling the cutting of various material specifications as well as thin materials.

Size and accuracy of contour.Size variation reduces the ability to meet placement requirements. In addition any dimensional deficiency would negatively influence the attractiveness of the product. This is particularly critical in the field of injection molding and thermoforming where an in-mould label would wrap around container.

Berhalter B 500 high performance die-cutting machine with eight up double output punching tool for web width up to 520 mm

Print-to-die registration.Where high quality is required, the customer would ask not only for high quality graphics with accurate print-to-print registration but also for perfect print-to-die registration.

Static charge of material.Die-cutting systems should be able to count and stack eg polyester lids automatically and have an integrated system to control the static charge of the film.

Die-cutting method. There are different cutting methods available on the market such as cutting with a steel-rule die, high die-cutting, rotary die-cutting and cutting with a male/female die. The Berhalter die-cutting system is a male/female punching tool which is perfectly suited for precise die-cutting of materials, including thin substrates and liners.

Other issues.Edges with burrs or ‘angel hairs’ caused by edge welding or other die-cutting deficiencies will cause picking problems at the de-stacking magazine resulting in missing lids or labels as well as displacement. It is also important that the clearance between cutting components is as small as possible. Berhalter produces cutting tools with microns of play enabling us to cut aluminum less than 13 microns or BOPP materials as thin as 40 microns or less.

Types of applications produced by the Berhalter B 500

The company’s inspection systems make it possible to inspect the print and material quality inline on the die-cutting machine. Defective material is passed through the tool area without being punched – delivering 100% controlled products. The high level of automation reduces downtimes, as seen with the automatic in-register reel changer REELsplicer, which improves capacity through increased machine utilisation and reduced downtimes. The fully automatic handling system BEAMstack makes it possible to separate accurately counted lid and label stacks and place them fully automatically into a pre-defined position.

Finally, the Berhalter PRElaser laser technology can be used for various areas of application. One of the target markets is multipack yoghurt lids, which can now be pre-perforated using the PRElaser so that the yoghurt pots can be individually snapped off and separated without the lid being removed.