Dupont has developed a range of photopolymer ITR sleeves

In the round printing is a small but growing niche that is helping flexo printers compete against gravure for longer run jobs. By Nessan Cleary.

The basic concept of In the Round (ITR) is to enable the printing of continuous designs without a join by using a flexo sleeve, which sounds simple enough until we remember that the flexo process was really designed to handle flat plates. The big advantage is that this enables flexo printers to compete for jobs that otherwise would automatically go to a gravure press. As such, the growing demand for in the round fits into an overall trend of flexo printers taking on work from gravure, cutting costs for customers and raising their own profit margins in the process.

Most suppliers agree that In the Round printing remains a niche but one that is growing steadily. There are a number of further advantages to using ITR sleeves. Firstly, there is none of the difficulties normally associated with trying to wrap a flat plate around a sleeve, so they can be loaded quickly onto a press and it is easier to ensure good registration. They should allow presses to run faster as there are no issues with plate lift, cylinder bounce and non-uniformity across the web. There is generally a lot less wear and they last for long runs. In addition, all of the vendors claim excellent ink transfer and so there is no real limitation in the substrates they work with, including tissues and paper towels as well as flexible packaging films and folding carton.

The main disadvantage is the high cost, which rules out their use for short run jobs. But for long runs, or even short runs that are printed regularly, the sleeves can be quite a bit more cost effective than flat plates. The other big problem is that they require a lot of storage space so they can be kept safely in racks or boxes. Dave Kershaw, sales director for Precision Printing Plates, explained, ‘It’s all about if they are dropped or if you store them badly on the floor and twist them towards you then the corners can get damaged.’

Photopolymer

There are two main approaches to creating ITR sleeves – direct engraving and photopolymer sleeves. Much of the current interest is driven by the photopolymer sleeves and in this market there are two main suppliers, DuPont and Flint.

Flint Group makes the nyloflex range. There is a choice of thin and classic photopolymer sleeves, which use a LAMS layer for the digital artwork. Flint claims good ink transfer with low dot gain. The company recently launched a new polymer formulation that should give increased process consistency due to improved copying characteristics. Flint also sells the Rotec range of adaptors for use with these sleeves, as well as nyloflex imager and processor units.

DuPont initially outsourced some of its manufacturing to Flint, but now produces all its own sleeves, having grown its capacity over the last three years with a new facility at Neu-Isenburg in Germany.

Stephan Riechert, DuPont’s global product manager for ITR, said that he is seeing double digit growth, with Germany being one of the main markets, closely followed by the UK. He said, ‘Compared to the volume we see in plates, it is a niche market but it is not just about replacing plates. Our target is to offer flexo printers the ability to take on jobs that they couldn’t do before that went to direct engraving and rotogravure.’

Mr Reichert continued, ‘We believe that with photopolymer we can have much higher productivity and resolution than any direct engraved material.’ He said that the lasers used for direct engraving are limited, some in productivity and others in the materials they can handle, adding, ‘A photopolymer laser like a CDI can produce four to five sleeves an hour, imaged and processed, and none of the direct engravers have that productivity at high resolution.’

Another player worth mentioning in this area is Esko, which has developed its HD Flexo pre-press system that includes both the pre-press software and a range of CDI imagers and processors. Robert Bruce, UK sales account manager for Esko, said, ‘With our HD Flexo system we can tune it to make a round top or flat top dot.’ He added, ‘We have hundreds of different screening algorithms to match the plate with the screening with the customers equipment and how to get the best out of it.’

Pre-press

There are a number of pre-press companies specialising in ITR sleeves, including Precision Printing Plates, based in Manchester, which offers DuPont photopolymer sleeves imaged via Esko’s HD Flexo system. Sales director Dave Kershaw said the company has seen 20% growth year on year. He added that the image quality is extremely good. ‘The benefit of HD is the highlights and imaging at high resolution. It is the same process for HD sleeves as plates and we are getting as good a quality on sleeves as on plates.’ He said that the photopolymer plates are fairly quick to make, ‘We can produce a lot of sleeves each day because they only image in 15-20 minutes, then exposure, which is about 10 minutes and drying.’

Mr Kershaw also commented that customers are often forced to use ITR sleeves because the job needs the continuous design without a join, but they find that the sleeves worked so well they choose to use them again.

YRG Group also offers ITR sleeves, again mainly using the DuPont sleeves together with its own adaptors. James Tinker, a director with the company, said, ‘Customers are seeing increased productivity, faster set up, higher run speeds and so on.’ He added, ‘There’s certainly more requirements for this technology now simply because the flexo market is eating away at the gravure market, and it gets you a seamless background where there’s no join showing.’

Direct engraving

The more traditional method is to engrave the design directly to a rubber-covered sleeve. One of the main UK suppliers is Northwest Rollers, a family-owned business based in Runcorn, Cheshire. Sales manager Barry Dodgson said that the company is expanding through exports, adding, ‘Rubber is much more hard wearing than photopolymer which is why people choose this option.’

Mr Dodgson explained that the cost can be twice as much as photopolymer, but that rubber last considerably longer so that it is suitable for very long runs. It can take a couple of hours to make each roller but the process produces a very high image definition. He added, ‘The rubber sleeves mount the same as photopolymer, but with a laser engraved sleeve you can change the diameter to whatever you want. You can put 5 mm or 25 mm thickness of rubber so you don’t need as many carriers as with photopolymer in the round which tend to be very thin and need a bespoke carrier for each size.’

Kodak’s Flexcel Direct includes imagining engine, sleeves and workflow

Kodak produces its own alternative, Flexcel Direct. This is a direct engraving system using elastomer rubber sleeves. It is a complete system with imager, sleeves and workflow designed to work together. The imager uses a laser diode array, which Kodak said is cheaper and easier to replace than a conventional laser. The company also claims that the array will give lower energy consumption and high resolution.

The workflow is a major component, with Kodak claiming that its system allows for control over the shape of the relief image, including shoulder angle, relief depth and undercut. This all adds up to fairly high quality images that include line screens up to 150 lpi, allowing for fine text and for reverse lines to be printed at high press speeds.

Rossini also produces rubber covered ITR sleeves that are based on an elastomer polymer mix and has a laser for engraving.

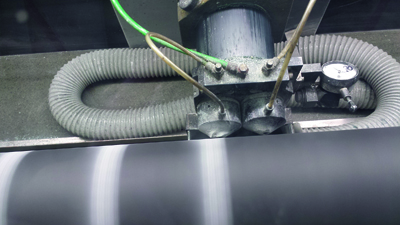

Laser engraving beam at work at Northwest Rollers

Adaptors

The photopolymer ITR sleeves generally require some form of adaptor to mount them to the press. Ellen Brimble, managing direcor of Rossini UK, said that these compressible adaptors have a relatively short life so that many customers have found this to be a considerable cost, adding, ‘It turns out to be a far more expensive option than they anticipated so we have customers that have reverted back and are buying plate sleeves again.’

However, Rossini is developing its own adaptors following customer requests. Ellen Brimble said, ‘We are looking at compressible adaptors and have some trials at a couple of customers. We have a slightly different design and the top layer is different to what is available on the market at the moment.’

Another supplier to watch in this area is Apex International, which has also been developing sleeve adaptors and plate mounting and is hoping to introduce a new product at drupa next year.

In conclusion, nobody expects ITR sleeves to replace plates, but their use is clearly growing. Most of this growth seems to be coming from the photopolymer plates though there is clearly a place for direct engraving to rubber, particularly on jobs with longer run lengths or many repeats. The high cost is the main drawback for most people but with more companies developing adaptors some of this cost may come down in the future and, of course, economies of scale will also play a part as the use of ITR becomes more widespread.