Common problems caused by lower quality or incorrect type of doctor blades include scoring of the anilox roller and UV ink spitting. Using a fit-for-purpose doctor blade will prevent issues, and it does not pay off to save on your metering equipment. By Neel Madsen.

Cutting corners is never advisable in flexo printing – a process that relies heavily on getting each element right in order for the press to output the highest quality print at high speeds with minimum downtime. The doctor blade is a small but essential part of this as it ensures the right amount of ink is transferred from the anilox to the printing plate, and however insignificant the doctor blade may seem, getting it wrong can cost you dearly.

‘I once heard a purchasing agent report that he spent more money on supplies for his facility’s restrooms than on doctor blades. I’m sure that same agent could not say the same thing about his expenditures on ink and substrate. With the doctor blade being a mission critical part of the printing process, purchase the best quality and most appropriate blade you can for your application and doctor blade related problems will be reduced or eliminated. Work with your doctor blade supplier to determine the best choice of material and profile for your doctor blades,’ advised Bill Warner, vice president, Allison Systems Corporation.

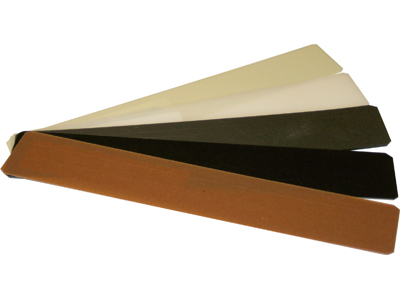

While steel blades still dominate, there are also many composite and plastic blades available, each with its own advantages. Blades vary in thickness, type of edges and can be coated or uncoated.

‘It is a necessity to be able to offer a wide range of doctor blade types since the needs vary from printer to printer, and also between printing methods. We also have to consider what inks are used, what type of product is printed and what substrates used when the best doctor blade choice is made,’ said Jonas Andersson, technical sales manager at PrimeBlade AB. ‘Another point to look at is the edge type, the choice of bevel, round, lamella or special edge. It is vital to choose the right one to achieve the optimal blade wipe and life time.’

Going for gold

Allison Gold and Laser Gold long life steel blades are developed for use with abrasive applications or long runs. Typical uses include white inks or other inks with high percentages of titanium dioxide or solids and/or rough anilox rollers. Gold blades can also help reduce anilox scoring issues. They are made from a tool steel alloy that wears in the form of a powder that is flushed away from the blade, avoiding the issue of wire burrs forming and breaking off as the blade wears and becoming trapped between the blade and anilox.

A laser hardening process can be applied to the working edge of the gold material to further increase wear resistance. Mr Warner commented, ‘Many customers who are using our Laser Gold material report that it is very effective at reducing UV ink spitting issues. The Gold series blades are more expensive than carbon or stainless steel blades, but the benefits they provide easily justify their added costs when compared to press downtime for blade changes during a run and scored anilox roller repair costs.’

A coating can be applied to steel blades to further extend their life and the life of the anilox roller. This will lower the coefficient of friction between the blade and anilox roller resulting in a clean wipe at lower pressures. Coated blades also offer enhanced corrosion resistance. Mr Warner said, ‘Try a coated blade in your application if you are looking for a little more life, less corrosion, or a cleaner wipe than you are currently getting from your uncoated blade.’

Composite and plastic

Fibreglass composite doctor blades can provide longer anilox life at high speeds when compared to carbon or stainless steel blades. As their performance is near on a par with metallic blades with respect to fine screen metering, composite blades can be a good choice for most abrasive or high solids inks. There can be issues with surface ink remaining on the anilox however.

Composite blades are reinforced with glass fibres, which help them avoid deformation issues that plague un-reinforced plastic blades during a press run. Allison Fiberglass composite doctor blades are made from cryogenic grade stock that is free of voids and inclusions, which lower grade materials can contain. Common applications involve paper and board substrates, and line work. It also has graphite blades that made from fibreglass composite impregnated with graphite. These are typically used on larger ceramic anilox rollers for higher end graphics in corrugated applications. Composites can be used for doctor and containment blade applications and typical thicknesses range from 0.014 to 0.035 inches.

Plastic doctor blades provide a lower coefficient of friction on ceramic anilox surfaces and long life. However, as they are made from thicker material, these will leave the most surface ink on the anilox roll and provide less consistent print quality. Plastic blades have been proven to be very useful for flexographic printing is on the containment side of a chambered inker.

Scoring

‘We encounter many questions about common problems regarding doctor blades, but two frequent topics of conversation are roll scoring and UV ink spitting. The type of doctor blade used can make an impact on final print results plus, several steps can be taken before start up to prevent score lines and UV spitting from occurring. The MDC Soft Blade is recommended to combat score lines and the MDC One-Step Doctor Blade has been proven to successfully reduce or eliminate UV spitting,’ said Olaf Segbert, head of sales and marketing at Daetwyler SwissTec AG.

Scoring shows as thin, circumferential lines that appear on the anilox roller during a press run. These lines show across the length of the roller and can range from light streaking to deep, dark streaks, which are clearly visible to the naked eye. Chamber or holder alignment, chamber loading pressure, and the condition of the anilox surface are all factors that can affect scoring.

Mr Segbert explained that chamber or holder alignment is key to a successful run and quality print. He said, ‘As the doctor blade chambers age, wear and tear by bending and twisting causes some form of distortion to the holder itself. Because of this alteration, the holders may not line up parallel, and the operator may put extra pressure on the assembly to try to compensate. Typically, the blade that touches the anilox first must deflect in order for the doctor blade to make contact with the anilox roller. It is important that the doctor blade extension is completely seated or resting against the stops in the holder and that all blades touch the roller simultaneously.’ Other factors, such as the holder not being cleaned properly, can also interfere with the misalignment of the blade set up.

Improper chamber loading pressure also contributes to score problems. Mr Segbert said, ‘As a rule, remember the required pressure is as little as possible and as much as needed.’

The surface of the anilox is another major factor, as uneven cell walls or excessive recast will affect the process. ‘If the anilox surface has a large amount of high spots, it may be necessary to polish the engraving, but, by post polishing, the cell walls become distorted and compromise the engraved cells from end to end, therefore minimising the consistency of the ink film. The higher the line count anilox roller, the higher chance of scoring the anilox roller, commented Mr Segbert.

The MDC Soft Blade from Daetwyler SwissTec has been developed to deal with the above issues and minimise scoring. This is a nickel-coated blade for solvent and water-based inks, available in widths from 8.5 to 80.0 mm, and five thicknesses from 0.150 to 0.500 mm.

Spitting

UV inks behave very differently on press compared to solvent and water-based inks, and the issue of ‘ink spitting’ is much discussed amongst all suppliers. While many companies and experts have found ways to minimise the problem, from the doctor blade perspective, doctor blade experts have researched this phenomenon by focusing on the specific characteristics of the doctor blade.

Mr Segbert explained, ‘Because UV ink has a higher viscosity and transfers differently, there are some physics that take place at the transfer point between the engraved cylinder, doctor blade and plate cylinder. Due to its thixotropic properties [it becomes less viscous when agitated -ed.], when the UV ink is transferred from the anilox roller, metered by the doctor blade and transferred to the plate, the ink frequently does not release without spraying. The result is the appearance of ink droplets on the print that are referred to as ‘spitting’.’

Thicker doctor blades can minimise spitting, such as those used in coatings and adhesives applications, but these may not deliver a thin enough ink film for high quality graphics.

On the left the image shows the ink build up causing the balde to flex, allowing the ink to drool under that part of the blade and sbsequently transfer onto the plate. On the right we can see by stiffening the blade, this can be prevented.

The MDC One-Step blade has been engineered to be thicker at the base (where the blade is installed in the holder) and extend close to the contact metering point. The tip of this blade is designed to maintain the same quality and characteristics of standard edge. The design allows the thicker ink to meter itself just like a normal doctor blade, but because of the strengthened base, the amount of flex is decreased therefore creating ‘consistent ink film metering’ without creating the ink hydroplaning effect behind the blade. This, in effect, eliminates or substantially lessens UV spitting, according to the company.

Swedish steel

Swedev’s SWED/CUT doctor blades product range covers all types of blades, from plastic or composite materials to blades made of extremely high alloyed and corrosion free steel which is then ground, in some cases surface coated and refined for various applications.

Sören Ågren, Swedev’s director of marketing and sales, said that the increase in high definition printing is seeing an increase in demand for coated blades to ensure a clean wipe. At the same time, blades need to last longer to match the longevity of the anilox rollers. The company’s MicroKote blade series offers a lubricating and wear-resistant coating, which decreases friction and resists the sticking of ink and particles near the tip of the blade, thereby minimising the risk of streaks and lines.

For longer runs and less blade changes, Swedev has the M-Flex+ blade which is made of a special alloyed carbon steel with higher yield strength offering higher hardness and longer blade life. It is produced with an extra refining step, which gives it a higher purity resulting in increased ductility for better flexibility and responsiveness.

The longer life MicroNox I&II series of blades are made from martensitic stainless steel and highly resistant to corrosion. This is particularly suitable in cases where the blade remains in the press long after the outer tip coating has been worn through and is subject to humidity.

Prime blades

‘PrimeBlade Sweden AB is a fairly young company, but we service printers worldwide with doctor blades, and are already a well-established brand on the market. The company has grown very fast mainly because we have highly skilled personnel in steel development, doctor blade production and printing itself, and offer a doctor blade range that enables printers to achieve a high quality print with good run economy. Furthermore, the use of high quality Swedish steel gives the advantages of longer blade life and cleaner print,’ said Jonas Andersson, technical sales manager.

The company has a wide range of doctor blades, from the basic 300 carbon steel blade for short runs to the long life 900 Nano III blade for very long runs and highly abrasive types of inks. It also offers plastic, high grade carbon, stainless steel and micro alloy tool steel blades.

The patented 900 Nano blade is produced by treating the base material to change the steel structure itself thereby eliminating the need for any coating. This method increase blade life and reduces friction, and it is an environmentally friendly way of producing long life doctor blades as no toxic waste products are created. The development of this new treatment procedure is ongoing, and the company will be releasing new products in the range.

Jonas Andersson

Mr Andersson explained how different grades of the steel raw material play a vital role in how fast the doctor blade wears down. To avoid issues with large microstructure carbide particles, which can increase wear and enter the ink system, causing damage to the anilox or gravure cylinder, PrimeBlade uses Swedish high quality steel, which has a dense distribution of a high number of small carbides. This offers better wear resistance and no harmful contamination of the ink.

He commented, ‘Unfortunately some printers are more concerned with the price of the blade than the performance, but the ‘cheaper’ blade can actually be more costly due to more frequent blade changes, and inferior performance. It is important to remember that one extra stop for blade changes in a production run is more costly than the cost of a high quality doctor blade.’

Asymmetry

Absolute Engineering supplies carbon fibre chamber systems and has over 5000 installations worldwide. The manufacturer has just introduced a range of asymmetrical chambers which promises to eradicate back doctoring issues and dramatically reducing ink loss.

Managing director, Antony Whiteside, explained, ‘The main problem when using standard symmetrical chambers is that, unless the anilox is perfectly clean, water-based ink can shift its position in the cell during rotation. When the blade is uppermost in a chambered blade system, surplus ink is wiped away by the retaining blade, creating back doctoring across the width of the chamber, wasting ink and making a mess. If, on the other hand, the retaining blade is uppermost, residue builds up on this blade before running to the end seals and dripping down. This is often confused with seal failure. Cleaning the roller thoroughly is of course vital to ensure correct transfer volumes, but this cleaning process is time-consuming, expensive and labour intensive.’

With its new range of asymmetrical profiles, Absolute is addressing these issues. The flatter angle of the retaining blade allows ink to re-enter the cells but prevents dripping, minimising or eliminating the back doctoring effect. The result is a cleaner process with less waste, increased efficiency and smoother, quicker production.

To achieve the optimal doctoring angle for wiping the cell surface completely clean, different profiles are needed to complement different anilox diameters. Absolute has produced different versions of the asymmetrical range to cover most applications, including corrugated pre-print, corrugated post-print and tissue.

Mr Whiteside is confident the range will prove a welcome boost for the packaging industry. ‘After developing our asymmetrical system, we’ve been trialling it ourselves with great success. Regardless of the materials printed, these chambers drastically cut ink loss and waste, keeping pace with modern processes.’

Final word

With so many different products on the market and so many different options, it is clear that expert help is needed. There might just be another type of doctor blade that will work better with the other components you are using.

Mr Andersson said, ‘We have to remember that a doctor blade can only perform optimal if the other parts in the print process are correct. A bad ink or anilox can only to a point be helped by a good quality doctor blade. A new or rough anilox surface will wear a blade faster and can create slivers that can damage the anilox surface. Also a badly grinded or poorly wetted ink pigment will decrease the lifetime of a doctor blade, while ink types like white, black, some red and blue and metallic inks wear a blade much harder than process colors. For these abrasive inks, in flexo printing, it can be a good idea to use a long life blade with thicker lamella or even a round edge.’